3D Printing

Transforming Ideas into Reality: Embrace the Power of 3D Printing!

3D Printing Services

What is 3D Printing ?

The fusion of 3D printing and CNC machinery has led to significant advancements in the manufacturing industry. 3D printing, also known as additive manufacturing, allows for the creation of three-dimensional objects by adding material layer by layer.

CNC (Computer Numerical Control) machinery, on the other hand, utilizes computer-controlled systems to precisely remove material from a workpiece to create intricate and precise shapes. The integration of these two technologies offers a powerful and complementary approach to manufacturing, providing enhanced capabilities, design freedom, and efficiency.

In this comprehensive guide, we will explore the principles of 3D printing in CNC machinery, its applications, materials used, advantages, challenges, and the future prospects of this innovative manufacturing process.

The Basics of 3D Printing in CNC Machinery :

- Additive Manufacturing (3D Printing): 3D printing, also known as additive manufacturing, constructs objects by depositing or fusing material layer by layer, based on a digital model. Common 3D printing technologies include Fused Deposition Modeling (FDM), Stereolithography (SLA), Selective Laser Sintering (SLS), and Metal Additive Manufacturing (Metal AM). The additive approach enables the creation of intricate and complex shapes with minimal material wastage.

- Computer Numerical Control (CNC) Machining: CNC machining employs computer-controlled systems to remove material from a workpiece, following specific toolpaths and instructions in G-code. Common CNC machining methods include milling, turning, and drilling. CNC machining offers high precision, repeatability, and versatility, making it ideal for creating intricate and customized components.

- Integration of 3D Printing and CNC Machining: The integration of 3D printing and CNC machining involves leveraging the strengths of both processes to optimize manufacturing outcomes. This integration can occur in various ways, such as using 3D printing to produce a near-net shape and then using CNC machining for precision finishing, or combining both processes in a single setup to achieve complex geometries and intricate designs.

Materials Used in 3D Printing in CNC Machinery :

- Polymers: Thermoplastics such as ABS, PLA, and nylon are commonly used in 3D printing, offering a balance of strength, flexibility, and ease of printing. These materials are often used in conjunction with CNC machining for finishing.

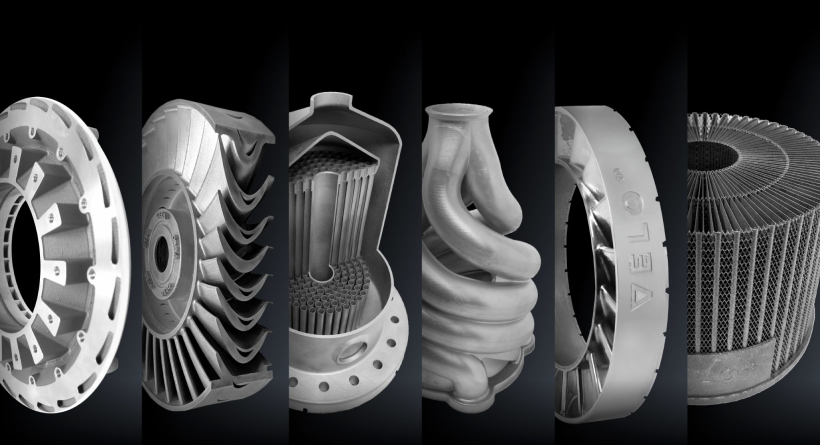

- Metals: Metal 3D printing, also known as metal additive manufacturing, allows for the production of high-strength, lightweight, and complex metal components. Materials such as aluminum, stainless steel, titanium, and nickel alloys are used for aerospace, automotive, and medical applications.

- Resins: Resin-based 3D printing offers high accuracy and detail, making it suitable for producing intricate and small-scale components with excellent surface finish. Resins are often used for applications in jewelry, dental, and medical fields.

- Composites: The integration of 3D printing in CNC machinery allows for the creation of components using composite materials, which combine different materials to achieve specific properties. Composite materials can offer enhanced strength-to-weight ratios and tailor-made performance characteristics.

Future of 3D printing in CNC machinery :

- Hybrid Manufacturing Solutions: Seamless integration of 3D printing and CNC machining, optimizing material usage and achieving complex designs.

- Expanded Materials Portfolio: Advancements in materials science lead to a wider range of materials for diverse applications.

- Improved 3D Printing Techniques: Faster printing, higher resolution, and new printing methods enhance additive manufacturing capabilities.

- Smart and Connected Manufacturing: Industry 4.0 principles, IoT sensors, data analytics, and real-time monitoring optimize production processes.

- Sustainability and Green Manufacturing: 3D printing reduces waste, recycling, and sustainable materials contribute to eco-friendly practices.

- Miniaturization and Micro Manufacturing: Enabling intricate components for medical devices, electronics, and micro-optics.

- Industry-Specific Applications: Aerospace, healthcare, automotive, and electronics sectors benefit from customized, high-performance components.

The future of 3D printing in CNC machinery promises advanced manufacturing, offering efficient, flexible, and sustainable production processes.

Advantages of 3D Printing in CNC Machinery :

- Design Flexibility: The integrated approach allows for the production of complex geometries and designs that are difficult or impossible to achieve with traditional machining methods.

- Reduced Material Waste: 3D printing in CNC machinery minimizes material waste as it only adds material where needed, optimizing material usage and cost efficiency.

- Rapid Prototyping and Iteration: The combination of 3D printing and CNC machining enables rapid prototyping and iterative design improvements, reducing product development cycles and time to market.

- Customization and Personalization: The flexibility of 3D printing in CNC machinery allows for the customization and personalization of components, catering to individual customer needs.

- Enhanced Efficiency: The integration of both processes streamlines production and reduces post-processing requirements, resulting in improved manufacturing efficiency.

- Improved Complexity and Functionality: 3D printing in CNC machinery enables the creation of parts with intricate internal structures, enabling enhanced functionality and performance.

- Reduced Tooling Costs: In certain cases, the combination of 3D printing and CNC machining can reduce tooling costs as complex geometries can be directly produced without costly tooling.

- Hybrid Materials and Properties: Combining different materials and processes allows for the creation

How Shivay Enterprise is different from other 3D Printing companies:

- Integrated Services: Shivay Enterprise offers seamless integration of 3D printing and CNC machining, providing comprehensive manufacturing solutions from prototyping to finishing in one facility.

- State-of-the-Art Technology: Utilizing the latest and most advanced 3D printing and CNC machining technologies, Shivay Enterprise ensures precision and efficiency in its manufacturing processes.

- Expertise and Experience: With a skilled team and extensive industry experience, Shivay Enterprise possesses the knowledge and proficiency to handle diverse projects and deliver exceptional results.

- Wide Material Selection: Shivay Enterprise provides a diverse range of materials for 3D printing and CNC machining, enabling customers to choose the best-suited materials for their specific applications.

- Customization Options: Shivay Enterprise offers personalized solutions, working closely with customers to understand their unique requirements and delivering tailored services.

- Emphasis on Quality Control: Shivay Enterprise follows strict quality assurance protocols throughout the production process, ensuring high-quality output and dimensional accuracy.

- Cost-Effective Solutions: Despite offering top-notch services, Shivay Enterprise maintains competitive pricing through efficient production processes and reduced material wastage.

- Diverse Industry Applications: Shivay Enterprise caters to various industries, showcasing its expertise in aerospace, automotive, medical, electronics, and consumer goods.

3D Printing is used in a wide variety of applications, including:

- Research and Development: Scientists use 3D printing for rapid prototyping of experimental setups and custom laboratory equipment.

- Military and Defense: The defense sector employs 3D printing to manufacture specialized equipment, prototypes, and spare parts on demand.

- Electronics and Robotics: 3D printing assists in the creation of casings, enclosures, and prototypes for electronic devices and robotics components.

- Food Industry: 3D food printers are used to create novel food designs, personalized nutrition, and customized confectioneries.

- Medical and Biotechnology: The medical field relies on 3D printing for anatomical models, surgical guides, and patient-specific medical devices, advancing personalized healthcare.

- Architecture and Construction: Architects and construction firms use large-scale 3D printers to create architectural models, intricate building components, and even entire houses.

- Aerospace: 3D printing is utilized to manufacture lightweight and complex aerospace components, reducing the overall weight of aircraft and enhancing fuel efficiency.

How Shivay Enterprise can help you with 3D Printing servicing:

- Rapid Prototyping: Quick turnaround for functional prototypes to validate design concepts.

- Customized Manufacturing: Tailored solutions for personalized products and components.

- Advanced Material Selection: Diverse range of materials, including polymers, metals, resins, and composites.

- Design Support: Expert assistance in refining and optimizing designs for 3D printing.

- Quality Assurance: Stringent quality control measures for precise and accurate prints.

- Post-Processing and Finishing: Options for enhancing appearance and performance.

- Efficiency and Cost-Effectiveness: Optimized processes for competitive pricing.

- Collaborative Approach: Engaging customers throughout the project to meet specific needs.

- Integration with CNC Machining: Seamlessly combining 3D printing with CNC machining for hybrid manufacturing solutions.

- Wide Range of Industries: Serving diverse sectors, such as aerospace, automotive, medical, and electronics.