Swiss & Micro Machining

Swiss machine servicing will help you get the most out of your machines, so you can produce high-quality parts and components on time and on budget, and exceed your customers’ expectations.

Swiss & MIcro machining Services :

Swiss machining and micro machining are both precision manufacturing techniques that excel in creating small, intricate parts with tight tolerances.

Swiss Machining Services:

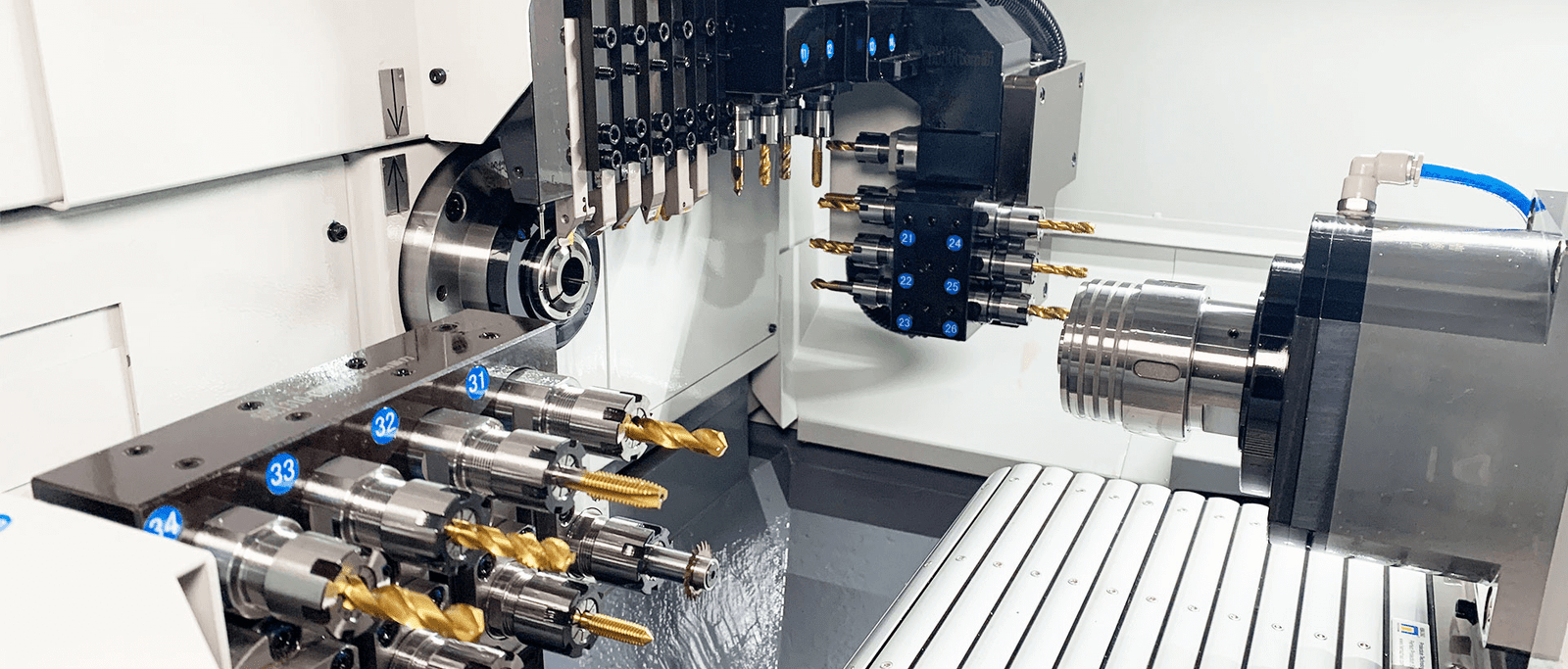

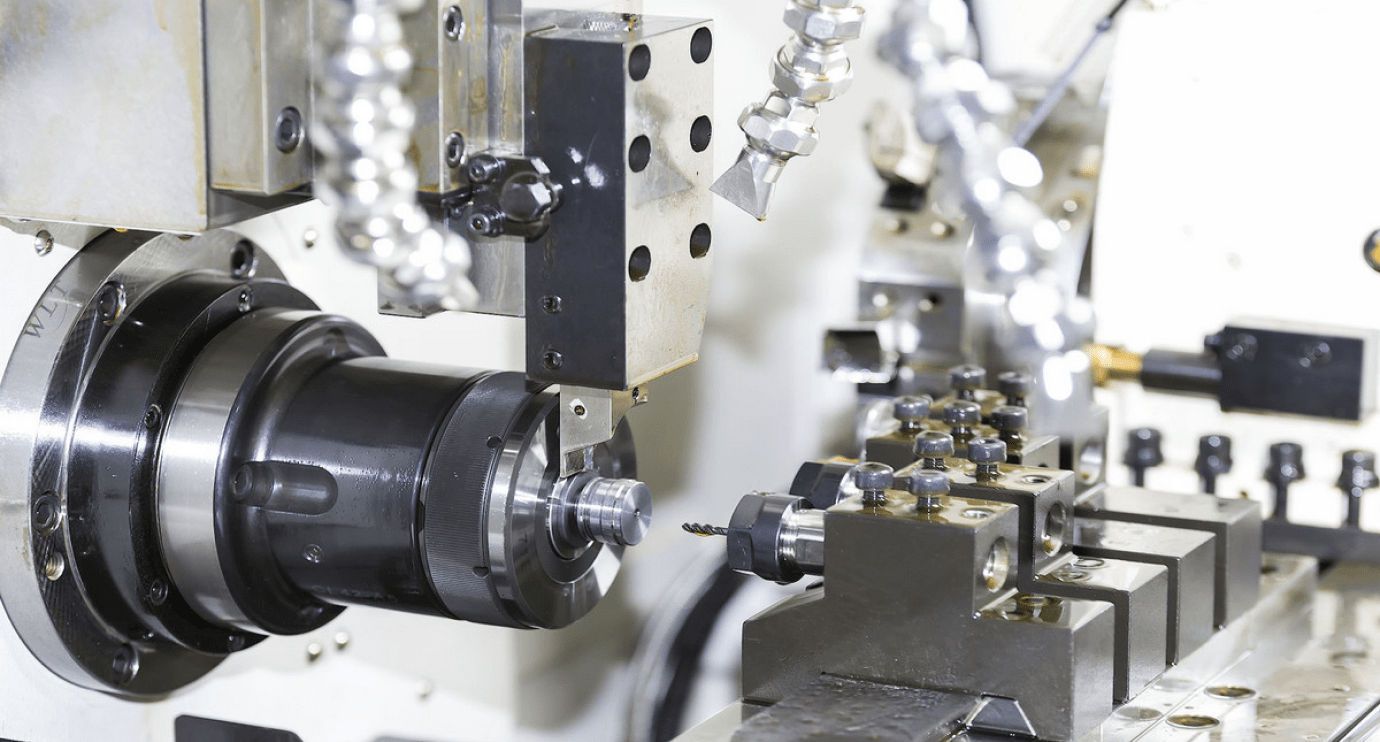

Swiss machining is a form of precision manufacturing renowned for its capability to produce small, complex parts with impeccable accuracy. Employing specialized CNC Swiss-type lathes, this process involves feeding material through a sliding headstock and a guide bushing while machining along the longitudinal axis of the machine.

Micro Machining Services:

Micro machining, on the other hand, refers to a manufacturing process that employs precision machine tools to craft parts with exceedingly small dimensions. It is typically utilized for components with dimensions of 0.1 mm or less. This process requires specialized techniques like micro milling, micro turning, micro drilling, and micro grinding to shape and form tiny components with intricate features.

How does it work?

Both Swiss machining and micro machining share a common focus on precision and accuracy. Swiss machining is a versatile process that employs advanced CNC Swiss-type lathes to create intricate parts with tight tolerances.

Meanwhile, micro machining is dedicated to crafting extremely small components using precision machining tools and techniques. These processes collectively contribute to various industries requiring intricate, high-precision components, with Swiss machining offering versatility and micro machining catering to the demands of miniaturization

The process of how different production systems work together in manufacturing involves a consideration of various factors such as the type of production, the steps in the production process, and the level of automation involved.

Types of Production Processes:

Mass Production: Mass production involves manufacturing many identical goods in a sequential manner. This method is characterized by standardized and repetitive processes that aim to keep manufacturing costs low by producing uniform products. Henry Ford’s Model-T automobile is a classic example of mass production, where each car turned out by the factory was identical. Mass-produced items include canned goods, over-the-counter drugs, and household appliances.

Mass Customization: Mass customization combines elements of both mass production and customization. The production process starts with standardized mass-production techniques, but at a certain point, customization is introduced to tailor products to individual customer preferences. For instance, American Leather, a furniture manufacturer, utilizes mass customization to produce couches and chairs with custom specifications within a short timeframe.

Customization: Customization involves creating goods or services one at a time according to the specific needs or desires of individual customers. Unlike mass production and mass customization, each product or service produced is unique. Examples include custom homes, legal services, and projects handled by job shops.

Here are some of the benefits of using Swiss & Micro machining :

- Swiss CNC machines are designed for precision manufacturing, suitable for producing small, intricate parts with tight tolerances.

- They perform multiple operations in a single setup, boosting efficiency and reducing the need for extensive secondary operations.

- The sliding headstock design minimizes material wastage by enabling precise machining close to the cutting tool.

- Swiss CNC machines are designed for machining small workpieces efficiently.

- This versatility accommodates diverse material requirements and applications.

- High speed, combined with precision, results in efficient manufacturing processes.

- CNC Swiss-type lathes offer shorter cycle times due to simultaneous turning and milling capabilities.

- It produces high-quality, intricate parts with critical dimensions, and meets specific specifications.

Incorporating Swiss and Micro machining into CNC production enhances precision, efficiency, and versatility, making it a valuable approach for producing intricate parts in various industries.

How Shivay Enterprise is different from other Swiss & Micro machining service companies:

- Shivay Enterprise’s focus on tailored solutions distinguishes them from companies offering generic services.

- The company’s commitment to innovation sets them apart from those adhering to conventional approaches.

- Shivay Enterprise’s versatile industry expertise surpasses competitors specializing in limited sectors.

- Their emphasis on client collaboration goes beyond the transactional nature of many service providers.

- Continuous improvement at Shivay Enterprise differentiates them from entities with stagnant practices.

- The company has a commitment to continuous improvement, refining processes, and adopting best practices.

- Shivay Enterprise excels in project management, adhering to timelines and delivering on schedule.

- Stringent inspections ensure the highest quality components are delivered to clients.

Shivay Enterprise’s combination of advanced technology, industry expertise, customized solutions, and a collaborative approach sets them apart from other Swiss & Micro machining service companies.

Swiss & Micro machining service used in a wide variety of applications, including :

- Aerospace: Swiss & Micro machining are crucial in aerospace for crafting lightweight, high-precision components used in aircraft engines, avionics, and structural elements.

- Medical Devices: Swiss & Micro machining are used to manufacture items such as surgical instruments, implants, catheters, and components for diagnostic equipment.

- Defense and Military: Swiss & Micro machining contribute to the production of intricate components used in defense applications, such as weapon systems, communication devices, and surveillance equipment.

- Semiconductor Industry: Micro machining is crucial for manufacturing semiconductor components and integrated circuits (ICs), where precision at a microscale is vital for functionality.

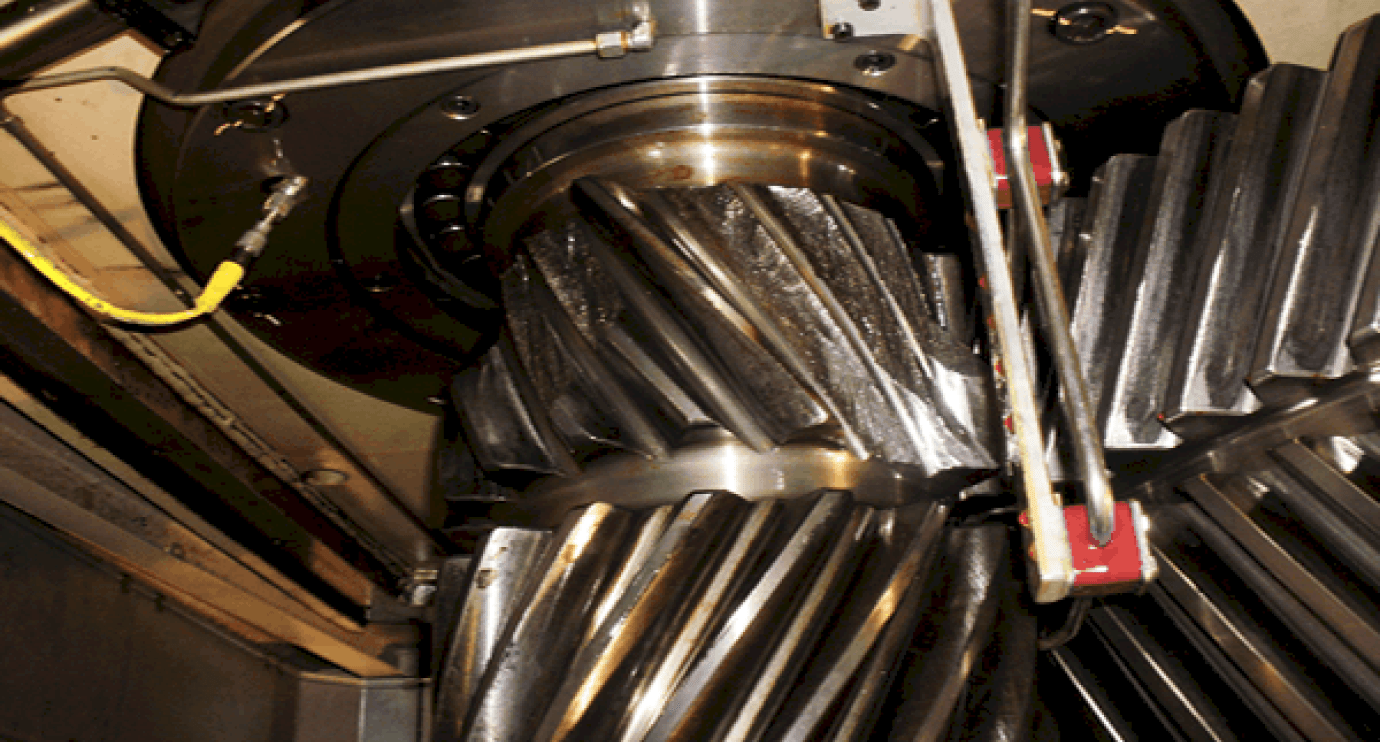

- Energy Sector: Components used in energy generation, transmission, and distribution benefit from Swiss & Micro machining for precise manufacturing of turbine parts, pumps, valves, and sensors.

- Precision Mechanics: Industries that rely on precise mechanical parts, such as robotics, automation, and scientific instruments, utilize Swiss & Micro machining for optimal performance.

The versatility of Swiss & Micro machining services allows them to cater to a broad spectrum of applications where precision, complexity, and high-quality components are required.

Here are some examples of real-world applications of Swiss & Micro machining:

- Aerospace Turbine Blades: Producing complex turbine blades with tight tolerances for aerospace engines, ensuring optimal performance and efficiency.

- Micro Optics: Manufacturing microlenses, mirrors, and prisms for optical devices used in cameras, laser systems, and scientific instruments.

- Surgical Instruments: Crafting precision surgical instruments like forceps, scissors, and microscopes used in minimally invasive procedures.

- Medical Implants: Crafting intricate and precisely dimensioned components for implants, such as bone screws, orthopedic plates, and dental implants.