5Axis Machining

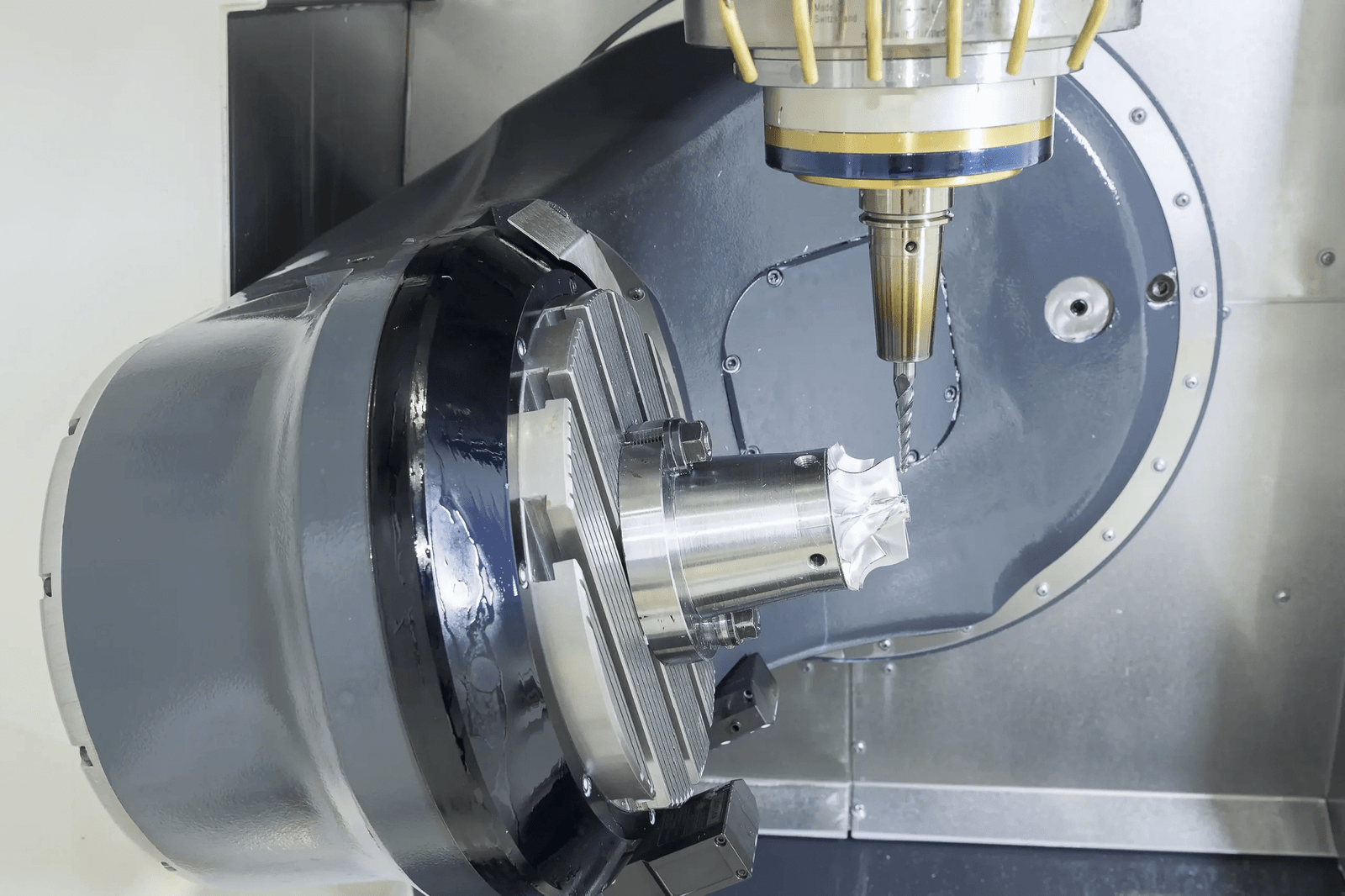

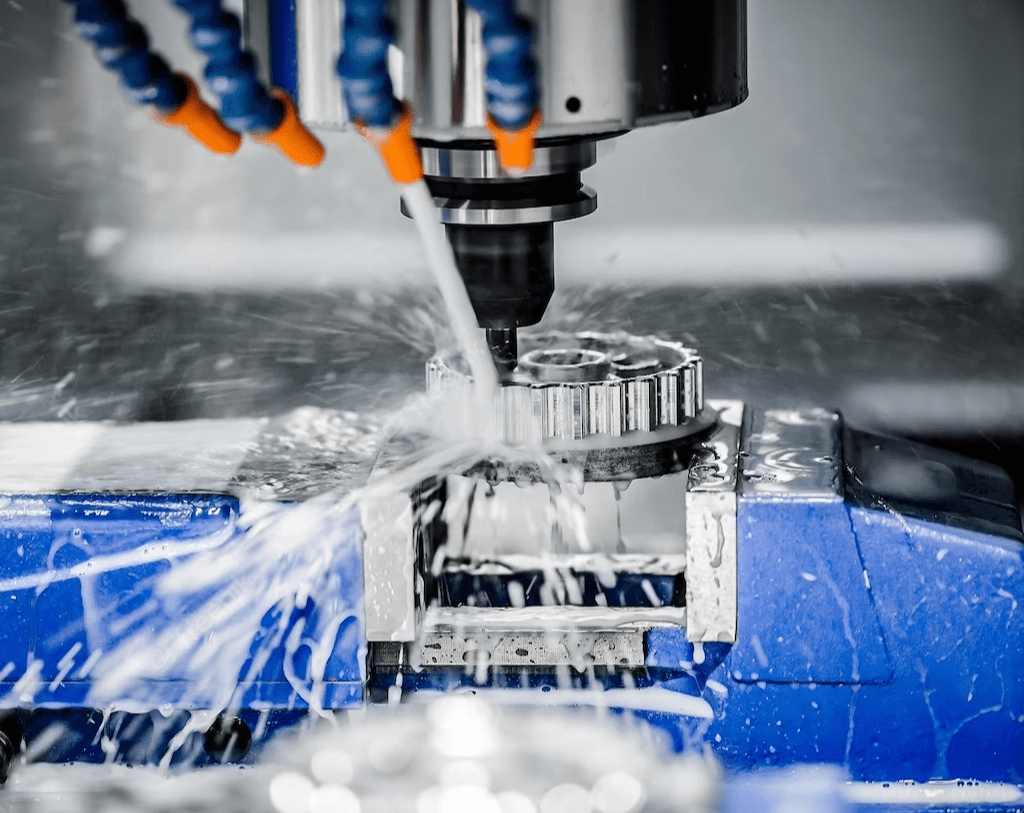

Shivay Enterprise provides 5-Axis Machining services that use precision machine tools to create parts with complex shapes and features.

5Axis Machining Services :

What is 5Axis Machining Services ?

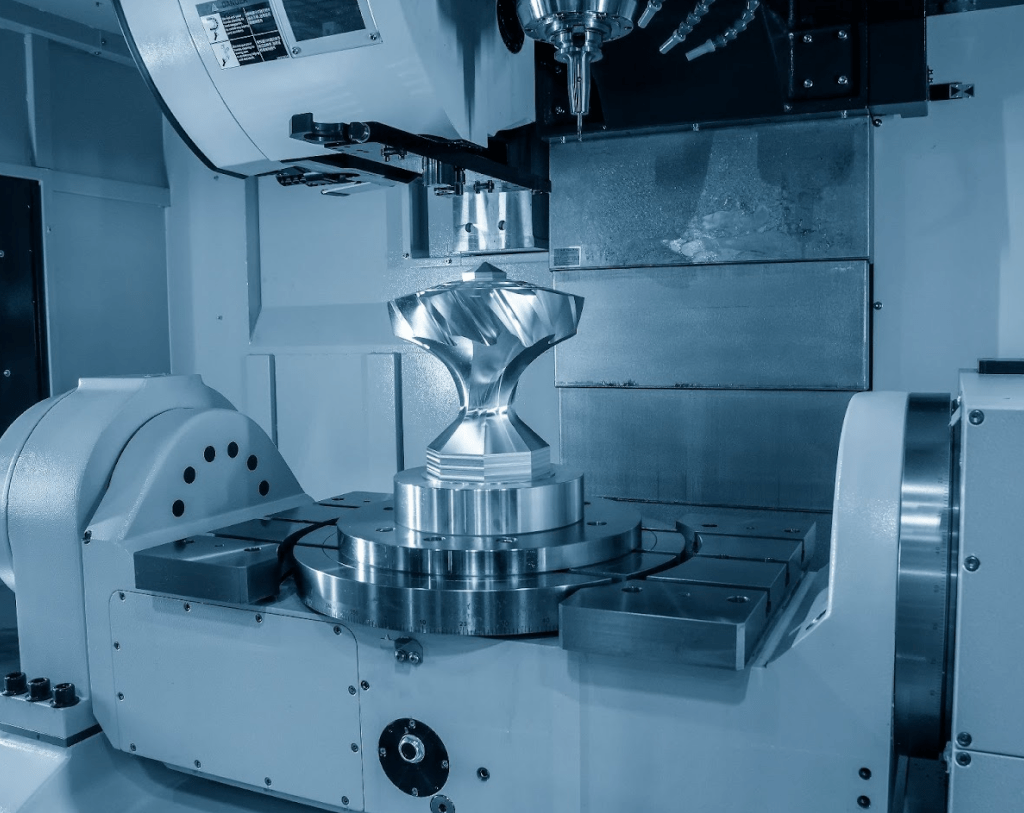

5-axis CNC machining is a type of machining in which the workpiece can be rotated in five axes, which allows for the creation of complex shapes and features that would be difficult or impossible to create with other machining processes.

Shivay Enterprise is a leading provider of 5-Axis Machining services in Surat, India. They have a team of experienced engineers and machinists who use the latest technology to create high-quality parts for a variety of industries.

5AxisMachining is a type of Computer Numerical Control (CNC) machining that allows the workpiece to be rotated in five axes. This means that the cutting tool can approach the workpiece from any direction, which allows for the creation of complex shapes and features that would be difficult or impossible to create with other machining processes.

- X-axis: The X-axis is the horizontal axis, which moves the cutting tool left and right.

Y-axis: The Y-axis is the vertical axis, which moves the cutting tool up and down.

Z-axis: The Z-axis is the depth axis, which moves the cutting tool in and out of the workpiece.

A-axis: The A-axis is the rotational axis around the X-axis.

B-axis: The B-axis is the rotational axis around the Y-axis.

Shivay Enterprise also provide tool suply service for 5 Axis Machining like,

- 5-Axis Milling: 5-Axis Milling is the most common type of 5 Axis Machining. In 5-Axis Milling, the cutting tool is used to remove material from the workpiece. The workpiece is rotated in five axes, and the cutting tool is moved in three axes. This allows for the creation of complex shapes and features that would be difficult or impossible to create with other machining processes.

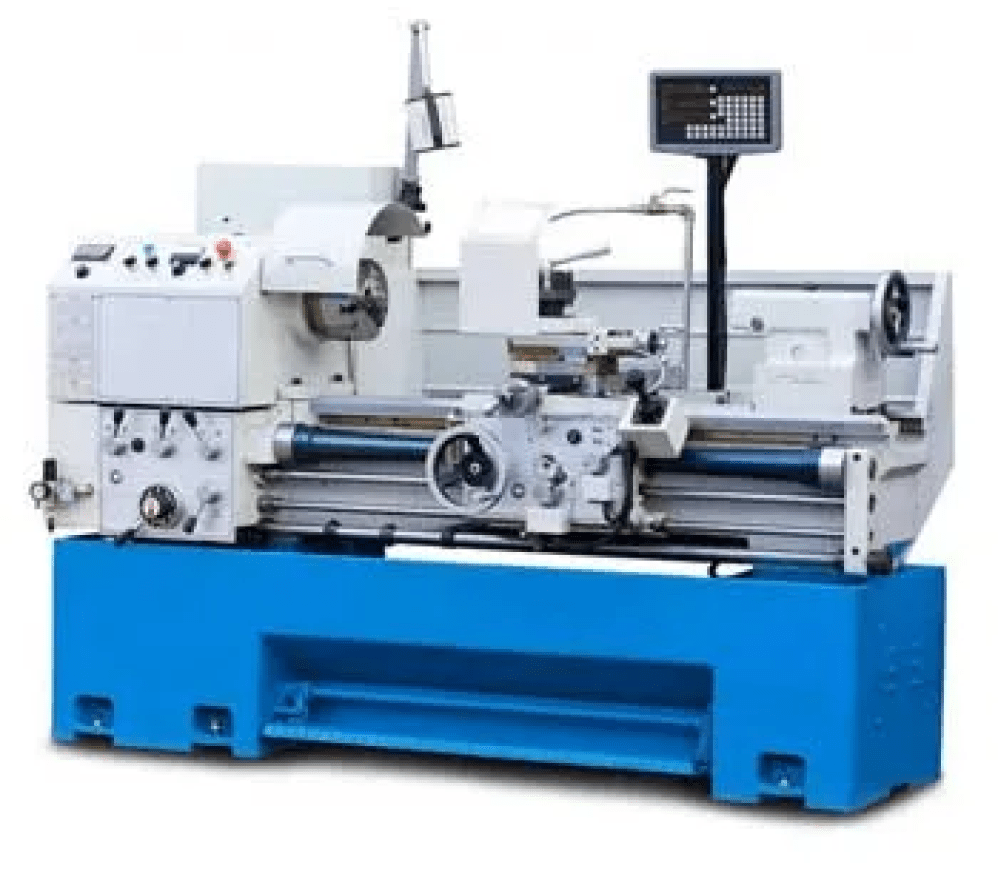

- 5-Axis Turning: 5-Axis Turning is a type of machining that is used to create cylindrical parts. In 5-Axis Turning, the workpiece is rotated in five axes, and the cutting tool is moved in two axes. This allows for the creation of complex shapes and features that would be difficult or impossible to create with other machining processes.

- 5-Axis EDM: 5-Axis EDM is a type of machining that is used to create complex shapes and features in conductive materials. In 5-Axis EDM, the workpiece is rotated in five axes, and a wire electrode is used to remove material from the workpiece by electrical discharge machining. This allows for the creation of complex shapes and features that would be difficult or impossible to create with other machining processes.

- 5-Axis Wire EDM: 5-Axis Wire EDM is a type of machining that is used to create complex shapes and features in conductive materials. In 5-Axis Wire EDM, a thin wire electrode is used to remove material from the workpiece by electrical discharge machining. The workpiece is rotated in five axes, which allows for the creation of complex shapes and features that would be difficult or impossible to create with other machining processes.

These are just a few of the most common 5 Axis Machining processes. There are many other types of 5 Axis Machining processes that are used in a variety of industries.

Shivay Enterprise is a leading provider of 5 Axis Machining and repair services. With over 4 years of experience, Shivay Enterprise has the expertise and equipment to meet your 5 Axis Machining needs. Contact Shivay Enterprise today to learn more about our services.

Here are some of the benefits of using 5AxisMachining:

- High precision: 5AxisMachining can produce parts with very high precision, down to a few microns.

- Fine surface finish: 5AxisMachining can produce parts with a very fine surface finish, down to a few nanometers.

- Versatile: 5AxisMachining can be used to machine a wide variety of shapes and features in a variety of materials.

- Complex shapes: 5AxisMachining can be used to machine complex shapes and features that would be difficult or impossible to create with other machining processes.

- Accuracy: 5AxisMachining can produce parts with very high accuracy, which is important for applications where tight tolerances are required.

- Surface finish: 5AxisMachining can produce parts with a very fine surface finish, which is important for applications where the surface finish is critical.

- Speed: 5AxisMachining can be faster than other machining processes, which can save time and money.

Contact Shivay Enterprise today to learn more about our Micromachining services.

How are we different from other 5-Axis machining companies ?

- Expertise: Shivay Enterprise has over 20 years of experience in 5-Axis machining. This experience gives us the knowledge and skills to create complex parts with high accuracy and surface finish.

- Technology: Shivay Enterprise uses the latest 5-Axis machining technology. This technology allows us to produce parts faster and with greater precision than other companies.

- Quality: Shivay Enterprise is committed to quality. We use only the highest quality materials and components in our machining process. We also have a strict quality control system in place to ensure that every part we produce meets our high standards.

- Flexibility: Shivay Enterprise is able to adapt to your specific needs. We can machine a wide variety of materials and produce parts in a variety of sizes and shapes.

- Cost-effectiveness: Shivay Enterprise is a cost-effective option for 5-Axis machining. We offer competitive prices and we can help you to save money by reducing your production costs

- We offer a wide range of services: In addition to 5-Axis machining, we also offer a wide range of other services, including CNC turning, EDM, and wire EDM. This allows us to provide you with a complete solution for your machining needs.

- We have a team of experienced engineers and machinists: Our team of experienced engineers and machinists is dedicated to providing you with the best possible service. We will work with you to understand your requirements and to develop a solution that meets your needs.

- We are committed to customer satisfaction: We are committed to providing you with the highest level of customer satisfaction. We will work with you to ensure that you are happy with your product and with our service.

If you are looking for a 5-Axis machining company that can provide you with the highest level of quality, expertise, and service, then Shivay Enterprise is the right choice for you. Contact us today to learn more about our services.

5-Axis machining is used in a wide variety of applications, including:

- Aerospace: 5-Axis Machining is used to create complex parts for aircraft and spacecraft. For example, 5-Axis Machining is used to create the blades of jet engines, the fuselage of airplanes, and the wings of helicopters.

- Medical: 5-Axis Machining is used to create precision medical devices, such as artificial implants and surgical tools. For example, 5-Axis Machining is used to create artificial heart valves, hip replacements, and surgical knives.

- Automotive: 5-Axis Machining is used to create complex parts for cars and trucks, such as engine components, transmission parts, and suspension components. For example, 5-Axis Machining is used to create pistons, gears, and shock absorbers.

- Manufacturing: 5-Axis Machining is used to create a wide variety of parts for a variety of industries, such as machine tools, robotics, and consumer electronics. For example, 5-Axis Machining is used to create CNC machine tools, robotic arms, and smartphones.

- Electronics: 5-Axis Machining is used to create precision electronic components, such as transistors, capacitors, and integrated circuits. For example, 5-Axis Machining is used to create the tiny components that makeup computers, smartphones, and other electronic devices.

Here are some examples of real-world applications of 5-Axis Machining:

- Artificial heart valves: Artificial heart valves are made of plastic and have complex shapes and features. They are machined using 5-Axis Machining to ensure that they are precisely engineered and have a smooth surface finish. This is important for the function of the artificial heart valve.

- Surgical knives: Surgical knives are made of steel and have complex shapes and features. They are machined using 5-Axis Machining to ensure that they are sharp and durable. This is important for the performance of the surgical knife.

- The spindle of a CNC machine tool: The spindle of a CNC machine tool is made of steel and has complex shapes and features. It is machined using 5-Axis Machining to ensure that it is strong and accurate. This is important for the performance of the CNC machine tool.

- The dies used to manufacture semiconductor chips: The dies used to manufacture semiconductor chips are made of silicon and have complex shapes and features. They are machined using 5-Axis Machining to ensure that they are perfectly accurate. This is important for the performance of the semiconductor chip

5Axis in Oil & Gas

5-axis machining is a versatile and precise manufacturing technique that is becoming increasingly popular in the oil and gas industry. As the demand for complex and high-precision oil and gas equipment continues to grow, 5-axis machining is likely to play an even greater role in the future of oil and gas manufacturing.

5-axis machining allows for the creation of parts with complex features that would be difficult or impossible to make with traditional methods. This gives designers more freedom to create innovative and new oil and gas products.

5Axis in Optic

5-axis machining is a versatile and precise manufacturing technique that is becoming increasingly popular in the optics industry. As the demand for complex and high-precision optical components continues to grow, 5-axis machining is likely to play an even greater role in the future of optics manufacturing.

5-axis machining allows for the creation of parts with much greater precision than traditional methods. This is important in optics manufacturing, as even small inaccuracies can lead to optical defects.

5Axis in Tool & Die

5-axis machining is a versatile and precise manufacturing technique that is becoming increasingly popular in the tool and die manufacturing industry. As the demand for complex and high-precision metal parts continues to grow, 5-axis machining is likely to play an even greater role in the future of tool and die manufacturing.

5-axis machining allows for the creation of parts with much greater precision than traditional methods. This is important in tool and die manufacturing, as even small inaccuracies can lead to product defects.

5Axis in Food Manufacturing

5-axis machining is a type of CNC machining that allows the cutting tool to move in five axes, or directions. This gives the machine a much greater range of motion than traditional 3-axis machines, and allows for the creation of complex and intricate parts.

5-axis machining is becoming increasingly popular in the food manufacturing industry, as it allows for the production of high-quality parts that would be difficult or impossible to make with traditional methods.