Medical

Shivay Enterprise provides CNC machine servicing to the medical sector. Their team of experienced machinists and engineers offers preventive, predictive, and corrective maintenance to keep CNC machines in top condition for life-saving procedures

Medical equipment Servicing facility

Keeping your medical CNC machines in top condition for life-saving procedures.

Shivay Enterprise provides CNC machine servicing to the medical sector. Their team of experienced machinists and engineers offers preventive, predictive, and corrective maintenance to keep CNC machines in top condition for life-saving procedures.

The medical sector relies on CNC machines to produce a wide range of critical components, including surgical instruments, medical implants, and diagnostic devices. These machines must be kept in top condition to ensure the accuracy and reliability of the parts they produce.

Shivay Enterprise’s team of experts has a deep understanding of the unique requirements of the medical sector. They offer a comprehensive range of CNC machine servicing services, including:

Shivay Enterprise’s team of experts is committed to providing the highest level of service to their medical sector clients. They understand that the quality of their work can literally mean the difference between life and death.

If you are a medical device manufacturer, you can trust Shivay Enterprise to keep your CNC machines in top condition so that you can continue to produce high-quality, life-saving products.

If you are looking for a reliable and experienced CNC machine servicing provider for your medical sector needs, contact Shivay Enterprise today.

Here are some of the benefits of working with Shivay Enterprise for medical CNC machine maintenance:

Shivay Enterprise is a leading provider of CNC machine maintenance services for the medical sector. They have a team of experienced machinists and engineers who are dedicated to providing their customers with the highest level of service.

- Expertise: Shivay Enterprise has a deep understanding of the unique requirements of the medical sector. They know what it takes to keep CNC machines in top condition so that they can produce high-quality, life-saving products.

- Quality: Shivay Enterprise is ISO 9001:2015 certified, which means that they have a proven track record of meeting and exceeding quality standards.

- Flexibility: Shivay Enterprise can customize its service plans to meet your specific needs, whether you need routine maintenance or emergency repairs.

- Peace of mind: Knowing that your CNC machines are being maintained by Shivay Enterprise gives you the peace of mind to focus on what you do best: saving lives.

CNC machines are used in the medical sector because they offer a number of advantages over traditional manufacturing methods, including:

- Surgical instruments: CNC machines can be used to manufacture a wide range of surgical instruments, such as scalpels, forceps, and needles. These instruments must be made to exact specifications in order to ensure patient safety.

- Medical implants: CNC machines can also be used to manufacture medical implants, such as hip replacements and pacemakers. These implants must be made to very tight tolerances in order to ensure they function properly.

- Diagnostic devices: CNC machines can also be used to manufacture diagnostic devices, such as X-ray machines and MRI scanners. These devices must be made with very high precision in order to ensure they provide accurate results.

- Dental tools: CNC machines can be used to manufacture a wide range of dental tools, such as drills, saws, and files. These tools must be made to exact specifications in order to ensure they are safe and effective.

- Ophthalmic instruments: CNC machines can also be used to manufacture ophthalmic instruments, such as contact lenses and intraocular lenses. These instruments must be made to very high precision in order to ensure they function properly.

- Laboratory equipment: CNC machines can also be used to manufacture laboratory equipment, such as centrifuges and microscopes. This equipment must be made with very high precision in order to ensure it provides accurate results.

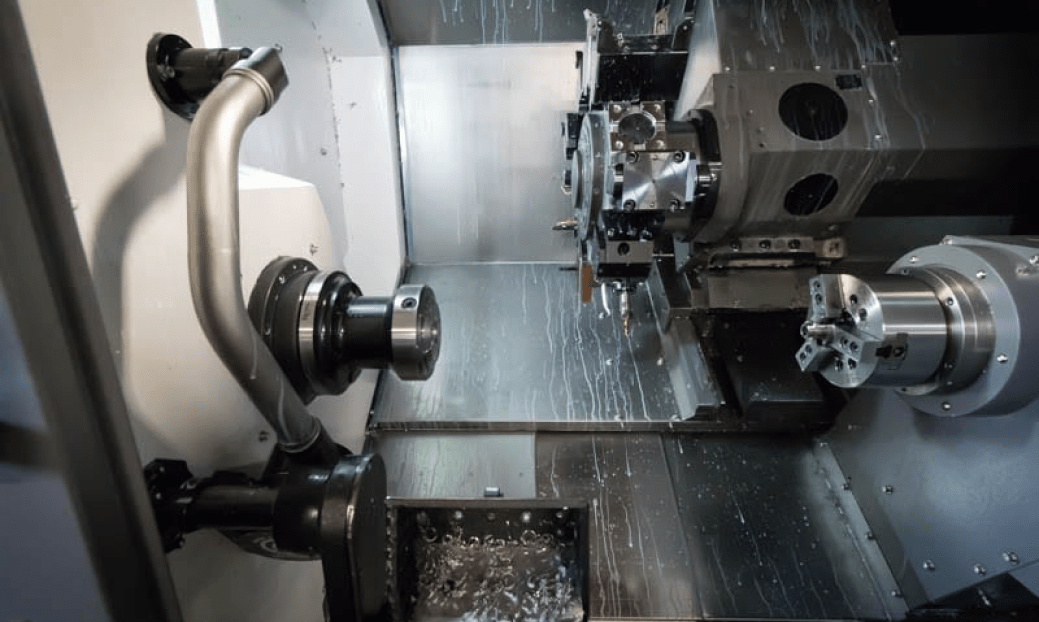

CNC machines are used in the medical sector because they offer a number of advantages over traditional manufacturing methods, including:

- Accuracy: CNC machines can produce parts with very high accuracy, which is essential for medical applications.

- Precision: CNC machines can produce parts with very tight tolerances, which is also essential for medical applications.

- Repeatability: CNC machines can produce parts that are identical to each other, which is important for medical devices that must be interchangeable.

- Speed: CNC machines can produce parts quickly, which is important for the medical sector, where there is often a high demand for medical devices.

CNC machines are an essential part of the medical sector, and they play a vital role in the manufacture of a wide range of critical components. The accuracy, precision, repeatability, and speed of CNC machines make them ideal for medical applications, and they help to ensure that patients receive the best possible care.

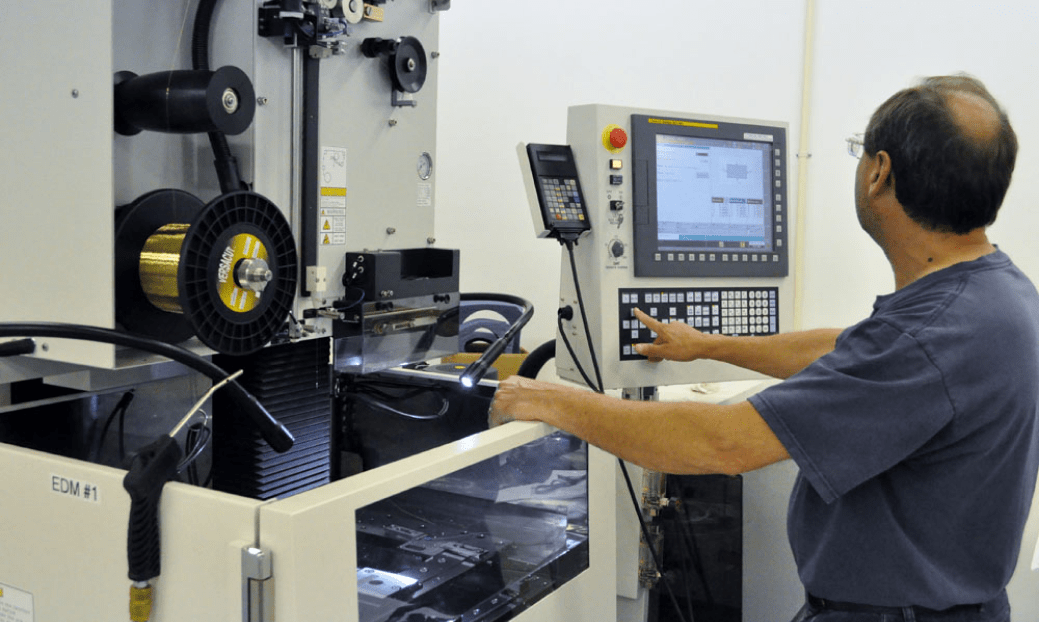

Services We Served In the Military/Defense Industry

- Laser Cutting Machines

- Wire EDM Machines

- CNC Milling Machines

- CNC Lathes

- CNC Machining Centers

- CNC Turning Centers

- CNC Grinders

- 3D Printers