Oil & Gas

Shivay Enterprise provides CNC machine servicing to the Oil & Gas sector. Their team of experienced machinists and engineers offers preventive, predictive, and corrective maintenance to keep CNC machines in top condition for mission-critical operations.

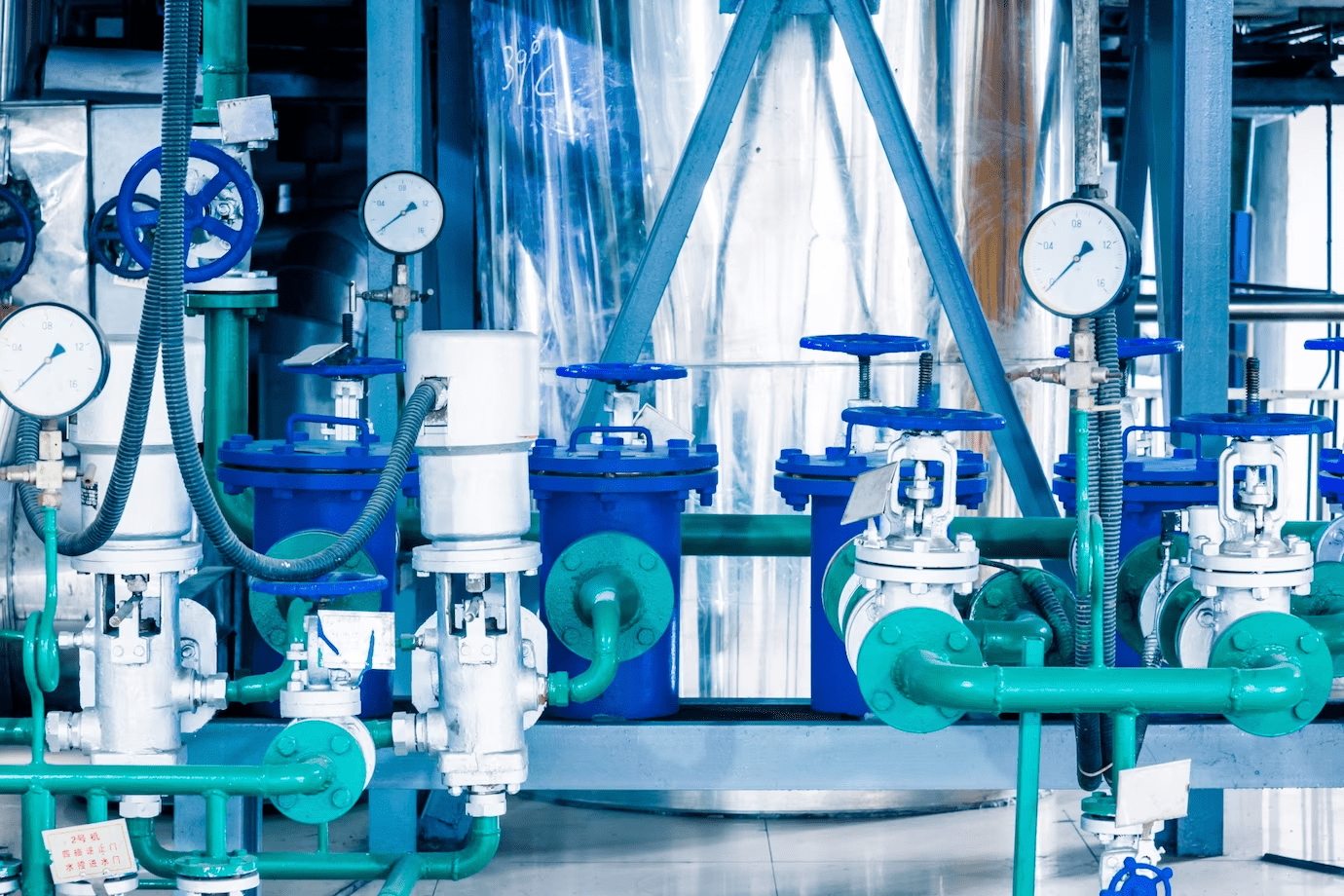

Oil and Gas equipment Servicing facility

Keeping your medical CNC machines in top condition for life-saving procedures.

The Oil & Gas sector relies on CNC machines to produce a wide range of critical components, including drill bits, valves, and pumps. These machines must be kept in top condition to ensure the accuracy and reliability of the parts they produce.

Shivay Enterprise’s team of experts has a deep understanding of the unique requirements of the Oil & Gas sector. They offer a comprehensive range of CNC machine servicing services, including:

- Preventive maintenance: This includes regular inspections and cleaning to identify and correct potential problems before they occur.

- Predictive maintenance: This uses data analytics to identify patterns of wear and tear so that problems can be proactively addressed.

- Corrective maintenance: This involves repairing or replacing components that have failed or are damaged.

Shivay Enterprise’s team of experts is committed to providing the highest level of service to their Oil & Gas sector clients. They understand that the quality of their work can literally mean the difference between life and death.

If you are an Oil & Gas company, you can trust Shivay Enterprise to keep your CNC machines in top condition so that you can continue to produce high-quality, mission-critical products.

By using Shivay Enterprise for your CNC machine maintenance needs, you can help to ensure that your machines are always in top condition and that you can continue to produce high-quality, mission-critical products.

How oil and gas companies use CNC machines in the production process:

CNC machines are used extensively in the oil and gas industry for a variety of applications, including the manufacturing of components for drilling equipment, valves, pumps, and pipelines.

- Drilling equipment: CNC machines are used to manufacture a wide range of components for drilling equipment, such as drill bits, stabilizers, and reamers. These components must be made to exact specifications in order to ensure they can withstand the harsh conditions of drilling operations.

- Valves: CNC machines are used to manufacture a wide range of valves for the oil and gas industry, such as control valves, safety valves, and check valves. These valves must be made to very tight tolerances in order to ensure they function properly.

- Pipelines: CNC machines are used to manufacture a wide range of components for pipelines, such as flanges, couplings, and elbows. These components must be made with very high precision in order to ensure they can withstand the high pressure and temperatures of oil and gas pipelines.

- Pumps: CNC machines are used to manufacture a wide range of pumps for the oil and gas industry, such as centrifugal pumps, reciprocating pumps, and positive displacement pumps. These pumps must be made with very high precision in order to ensure they can deliver the required flow rate and pressure.

CNC machines are used in the oil and gas industry because they offer a number of advantages over traditional manufacturing methods, including:

- Accuracy: CNC machines can produce parts with very high accuracy, which is essential for oil and gas applications.

- Precision: CNC machines can produce parts with very tight tolerances, which is also essential for oil and gas applications.

- Repeatability: CNC machines can produce parts that are identical to each other, which is important for oil and gas devices that must be interchangeable.

- Speed: CNC machines can produce parts quickly, which is important for the oil and gas sector, where there is often high demand for oil and gas devices.

CNC machines are an essential part of the oil and gas industry, and they play a vital role in the manufacture of a wide range of critical components. The accuracy, precision, repeatability, and speed of CNC machines make them ideal for oil and gas applications, and they help to ensure that oil and gas companies can operate efficiently and safely.

Advantages of using a maintenance service for CNC machines in the oil and gas industry :

- Preventing costly breakdowns: Regular maintenance can help to identify and correct potential problems before they cause a breakdown. This can save you a significant amount of money in repairs and downtime.

- Improving machine performance: Well-maintained CNC machines are more likely to operate at peak performance. This can lead to increased productivity and efficiency.

- Extending machine life: Proper maintenance can help to extend the life of your CNC machines. This can save you money in the long run by reducing the need to replace machines prematurely.

- Ensuring compliance with safety regulations: In some industries, such as oil and gas, there are strict safety regulations that must be followed. Regular maintenance can help to ensure that your CNC machines are in compliance with these regulations.

- Minimizing downtime: When a CNC machine breaks down, it can take time and money to get it back up and running. Regular maintenance can help to minimize downtime by identifying and correcting potential problems before they cause a breakdown.

If you are operating CNC machines in the oil and gas industry, it is important to have a maintenance plan in place. This will help to ensure that your machines are operating at peak performance and that you are minimizing downtime.

Here are some of the specific benefits of using a maintenance service for CNC machines in the oil and gas industry:

- Expertise: A maintenance service will have the expertise to properly diagnose and repair CNC machines. This can save you time and money in the long run.

- Availability: A maintenance service will be available to respond to machine problems quickly. This can help to minimize downtime and keep your production running smoothly.

- Peace of mind: Knowing that your CNC machines are being properly maintained can give you peace of mind. This will allow you to focus on other aspects of your business knowing that your machines are in good hands.

If you are considering using a maintenance service for your CNC machines, be sure to do your research and choose a reputable company. You should also make sure that the company has experience working with CNC machines in the oil and gas industry.

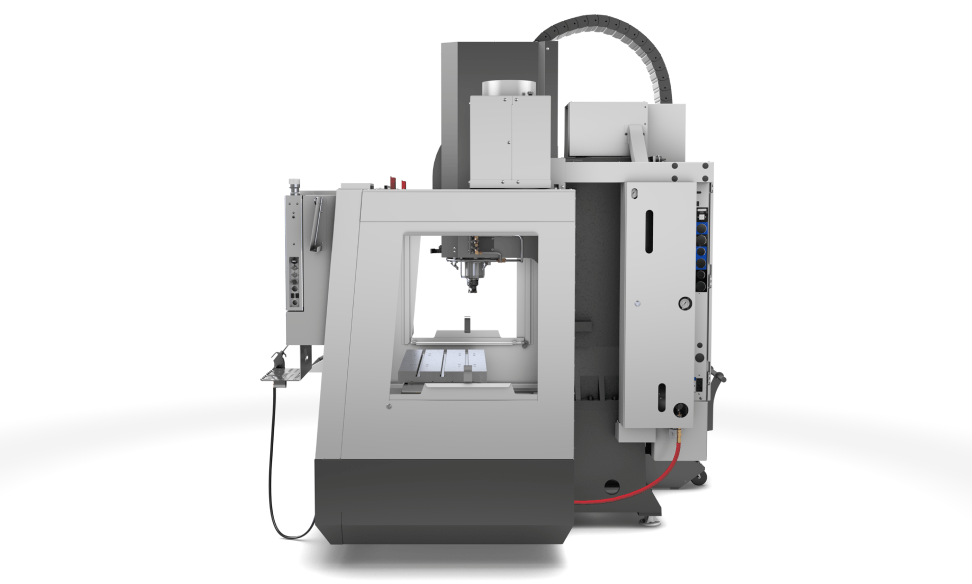

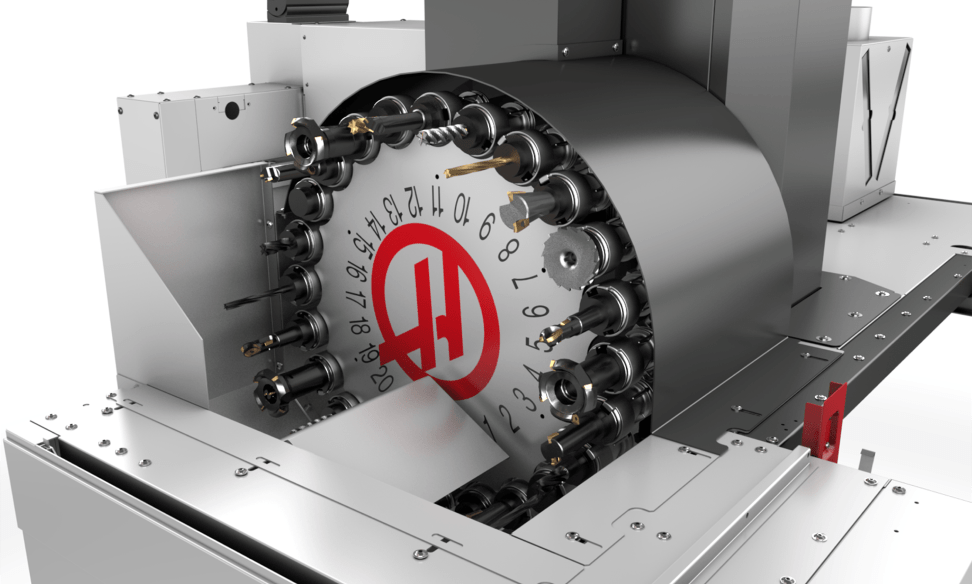

Services We Served In the Oil & Gas Industry

- DMG MORI NLX 2500

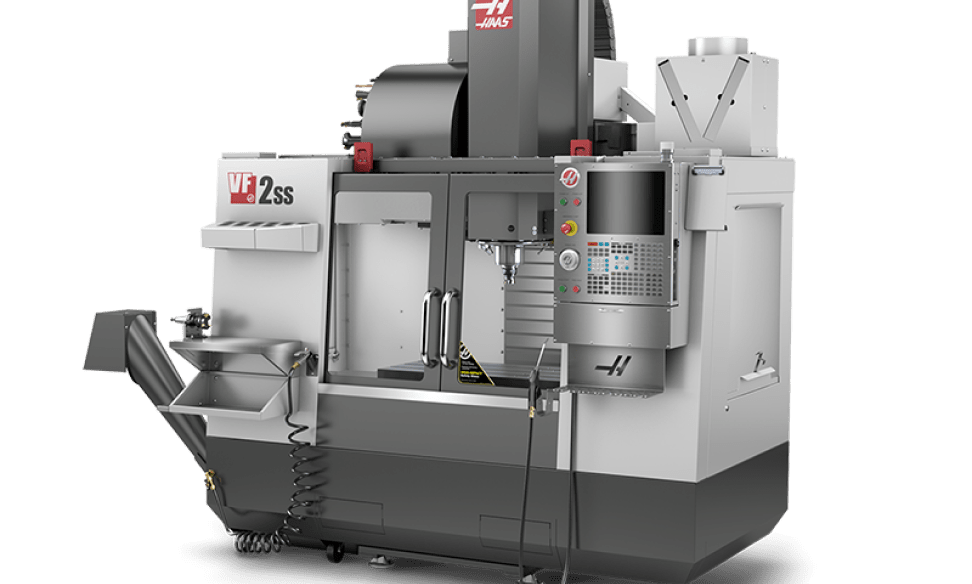

- Haas VF-2SS

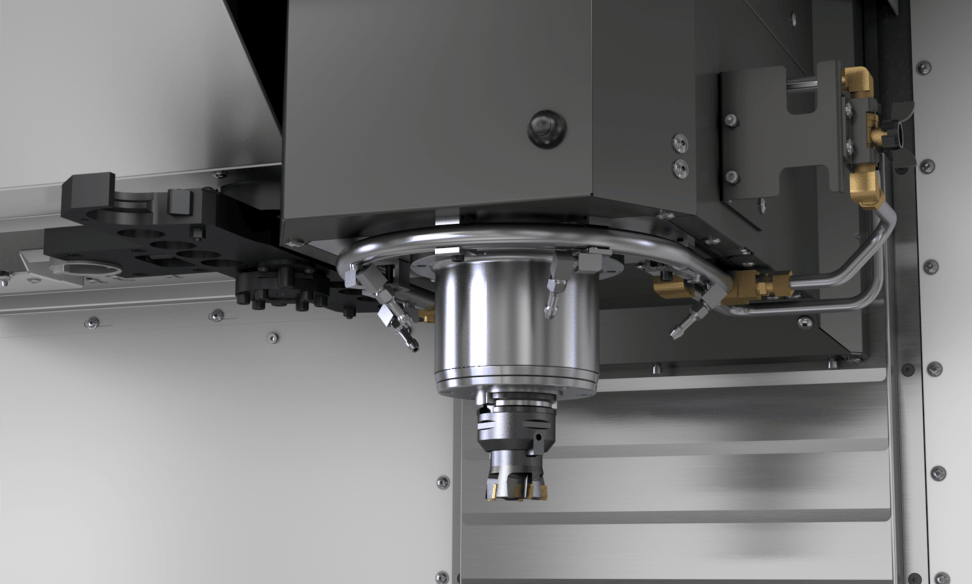

- Makino 5-Axis Vertical Machining Center

- Yamazaki Mazak Integrex i-400

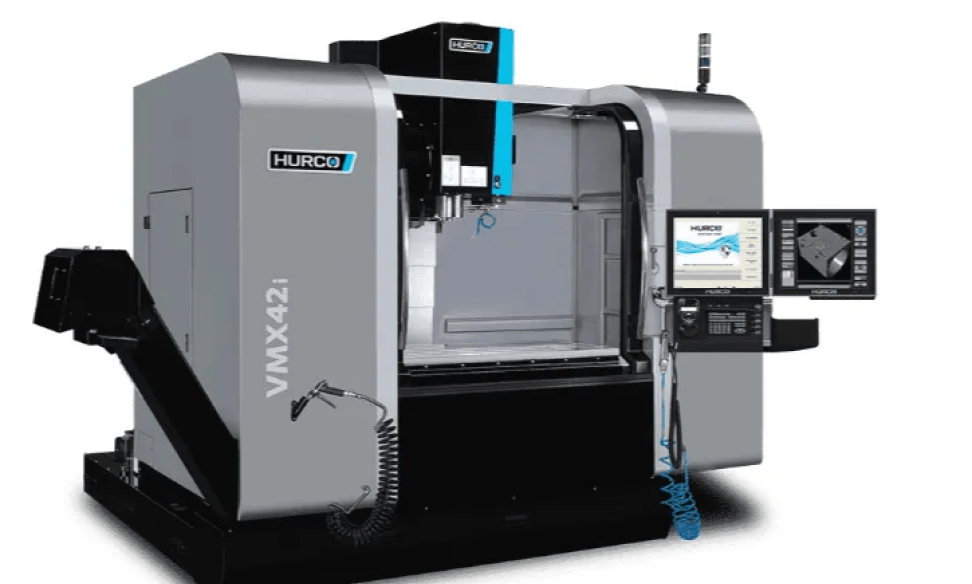

- Hurco VMX 1100

- GF MicroCut 500

- Okuma Genos M4600-V

- Trumpf TruLaser Cell 7040

- Bystronic BySmart 3015 fiber

- Mazak Optune 5-Axis Milling Machine