Energy

Shivay Enterprise is the future of energy maintenance. We are committed to providing our customers with the latest technologies and solutions.

Shivay Enterprise: The energy sector's maintenance experts

Shivay Enterprise is a leading provider of CNC machine maintenance services for the energy sector. They have a team of experienced engineers and technicians who are dedicated to keeping your CNC machines running smoothly and efficiently.

Shivay Enterprise has been providing maintenance services to the energy sector for over 20 years. We have a deep understanding of the challenges faced by energy companies and we are committed to providing you with the solutions you need to keep your systems running smoothly and efficiently.

Our team of experienced engineers and technicians are experts in all aspects of energy maintenance. We offer a wide range of services, including preventive maintenance, corrective maintenance, predictive maintenance, and condition-based maintenance. We also offer a variety of specialized services, such as turbine maintenance, generator maintenance, compressor maintenance, and pump maintenance.

We are committed to providing you with the highest quality of service at a competitive price. We understand that your energy systems are essential to your business, and we are dedicated to keeping them running smoothly and efficiently.

- Preventive maintenance: This type of maintenance is designed to prevent problems from happening in the first place. It involves inspecting and servicing your CNC machines on a regular basis to identify and address any potential problems before they cause downtime.

- Corrective maintenance: This type of maintenance is performed when a problem does occur. It involves repairing the problem so that the CNC machine can return to normal operation.

- Predictive maintenance: This type of maintenance uses data and analytics to identify potential problems before they occur. This allows Shivay Enterprise to take preventive action to avoid downtime.

- Condition-based maintenance: This type of maintenance is based on the condition of the CNC machine itself. It involves monitoring the machine’s performance and identifying any signs of wear or tear. This allows Shivay Enterprise to take corrective action before the problem causes downtime.

If you are looking for a reliable and experienced CNC machine maintenance provider, then Shivay Enterprise is the right choice for you. We can help you to keep your CNC machines running smoothly and efficiently so that you can focus on your core business operations.

Shivay Enterprise also offers a variety of specialized CNC machine maintenance services, such as:

- Turbine maintenance: Turbines are critical components of many energy systems. Shivay Enterprise can help you keep your turbines running smoothly and efficiently by providing regular maintenance and repairs.

- Generator maintenance: Generators are also essential to many energy systems. Shivay Enterprise can help you keep your generators running at peak performance by providing regular maintenance and repairs.

- Compressor maintenance: Compressors are used to compress air or gas. Shivay Enterprise can help you keep your compressors running smoothly and efficiently by providing regular maintenance and repairs.

- Pump maintenance: Pumps are used to move fluids. Shivay Enterprise can help you keep your pumps running smoothly and efficiently by providing regular maintenance and repairs.

Here are some additional details about the CNC machine maintenance services that Shivay Enterprise provides:

- We offer a variety of preventive maintenance plans to fit your budget and needs.

- We have a 24/7 emergency repair service to keep your CNC machines running when you need them most.

- We offer training on CNC machine maintenance to help you keep your machines running smoothly.

- We have a wide network of certified CNC machine technicians to provide you with the best possible service.

Advantages of Using Shivay Enterprise

There are many advantages to using Shivay Enterprise for CNC machine maintenance in the pharmaceutical industry. These include:

- Increased uptime: Shivay Enterprise’s preventive maintenance services can help to prevent problems from occurring in the first place, which can lead to increased uptime for your CNC machines. This means that you will be able to produce more parts and generate more revenue.

- Reduced downtime: If a problem does occur with your CNC machine, Shivay Enterprise’s quick and efficient repairs can help to minimize downtime. This means that you will be able to get your machines back up and running as soon as possible so that you can continue to produce parts and generate revenue.

- Improved quality: Shivay Enterprise’s preventive maintenance services can help to identify and correct any potential problems with your CNC machines before they cause quality issues. This can help you to ensure that your parts are always meeting your quality standards.

- Increased safety: Shivay Enterprise’s preventive maintenance services can help to identify and correct any potential safety hazards with your CNC machines. This can help to keep your employees safe and prevent accidents.

- Reduced energy consumption: Shivay Enterprise’s preventive maintenance services can help to identify and correct any potential energy inefficiencies with your CNC machines. This can help you to reduce your energy costs and save money.

- Increased productivity: Shivay Enterprise’s preventive maintenance services can help to keep your CNC machines running smoothly and efficiently. This can lead to increased productivity and improved bottom-line results for your business.

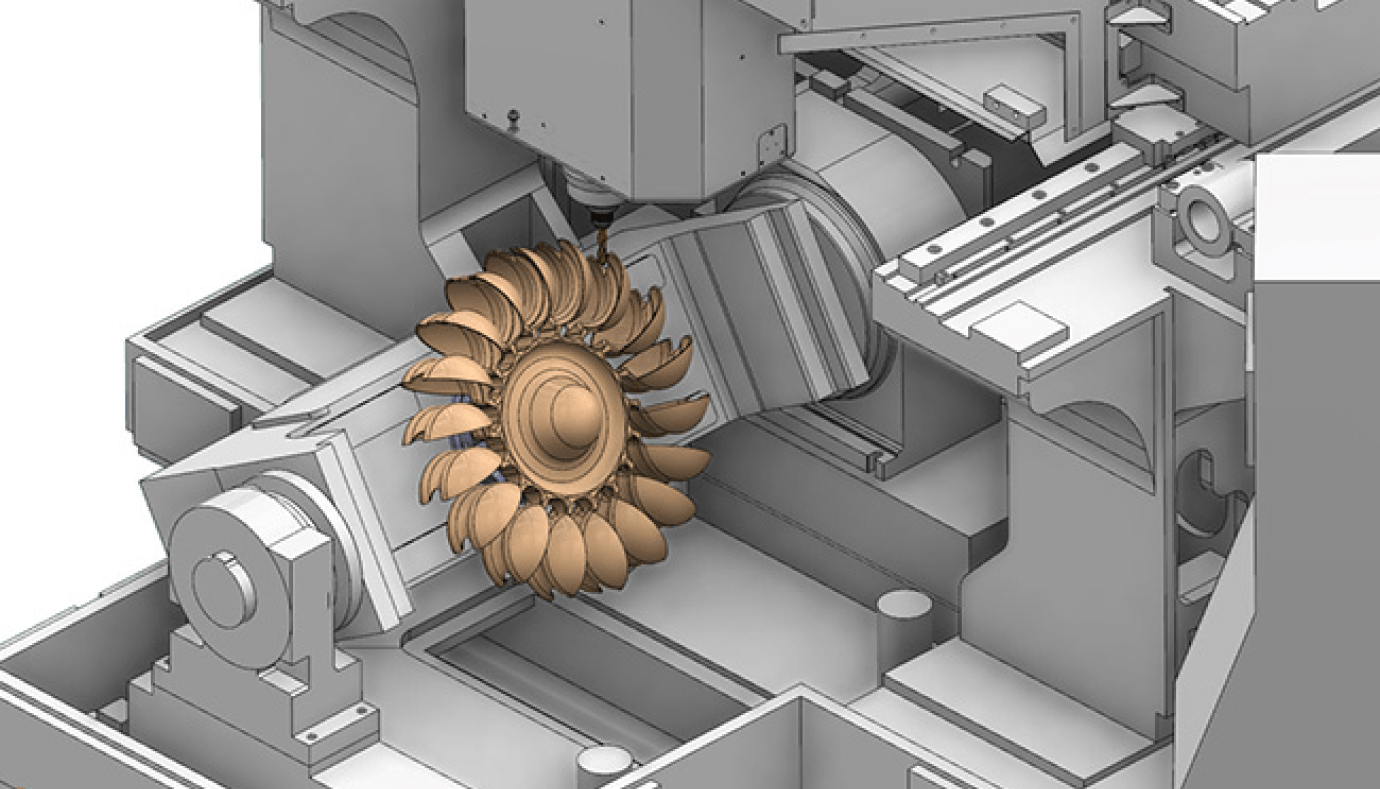

Types of CNC Machines Used in Energy Sector

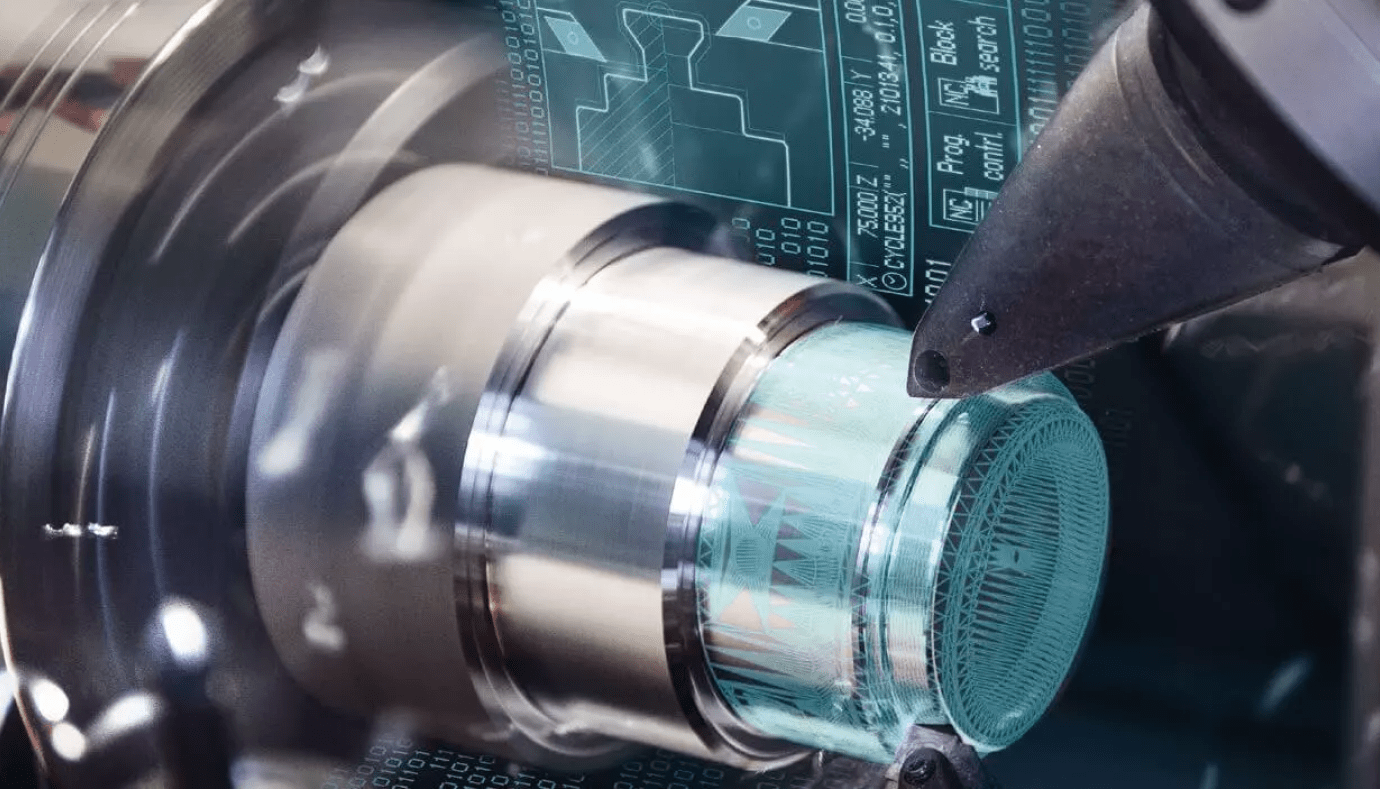

CNC milling machines: CNC milling machines are used for a variety of applications in the energy sector, including the manufacturing of turbine blades, generator rotors, and other components. CNC milling machines are able to cut and shape metal with great precision, which is essential for the safe and efficient operation of energy systems.

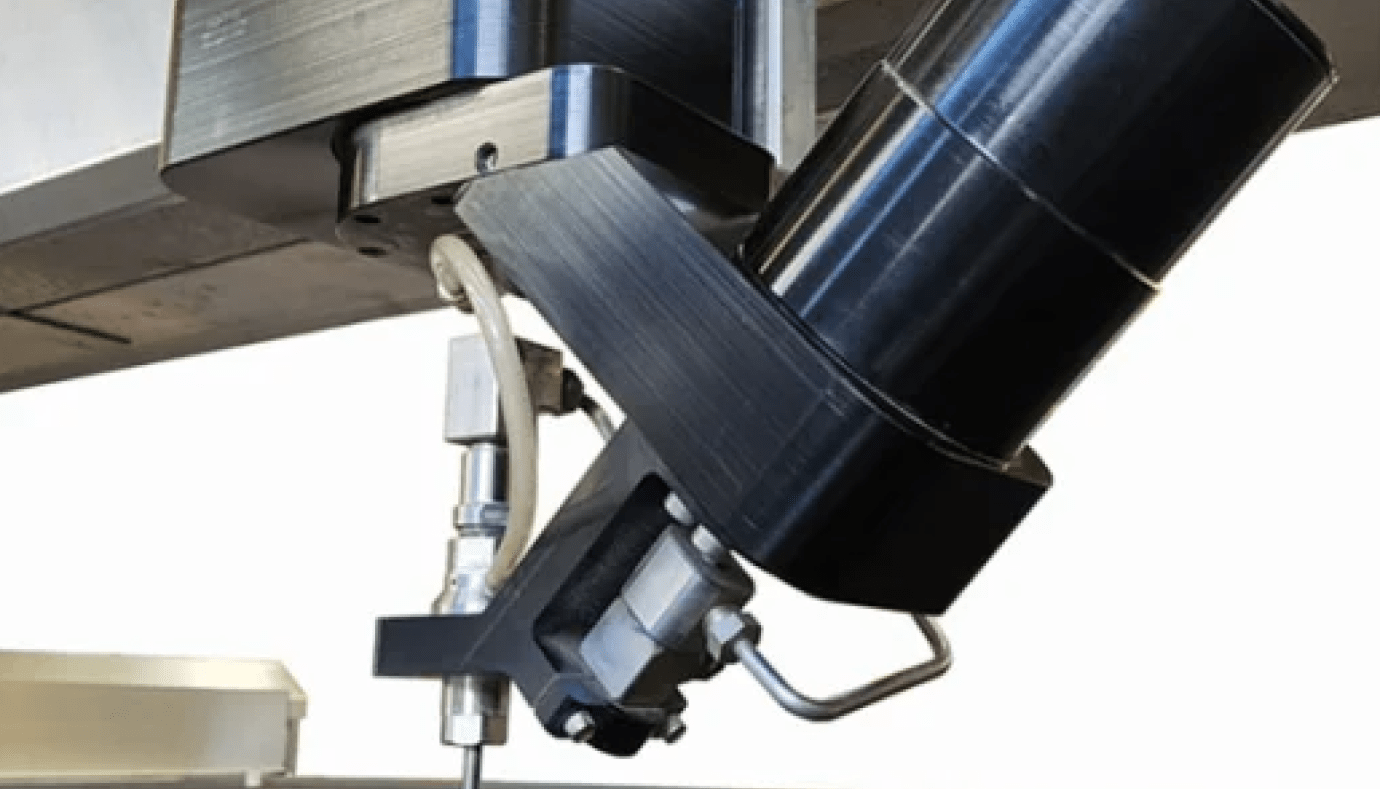

- CNC lathes: CNC lathes are used for a variety of applications in the energy sector, including the manufacturing of pipes, shafts, and other cylindrical components. CNC lathes are able to turn metal with great precision, which is essential for the safe and efficient operation of energy systems.

- CNC grinders: CNC grinders are used to smooth and polish metal surfaces. This is important for the energy sector because it helps to ensure that the surfaces of components are free of defects, which can lead to failures.

- CNC water jet cutters: CNC water jet cutters are used to cut metal, plastics, and other materials with a high-pressure water jet. This is a versatile tool that can be used for a variety of applications in the energy sector, such as the cutting of turbine blades and generator rotors.

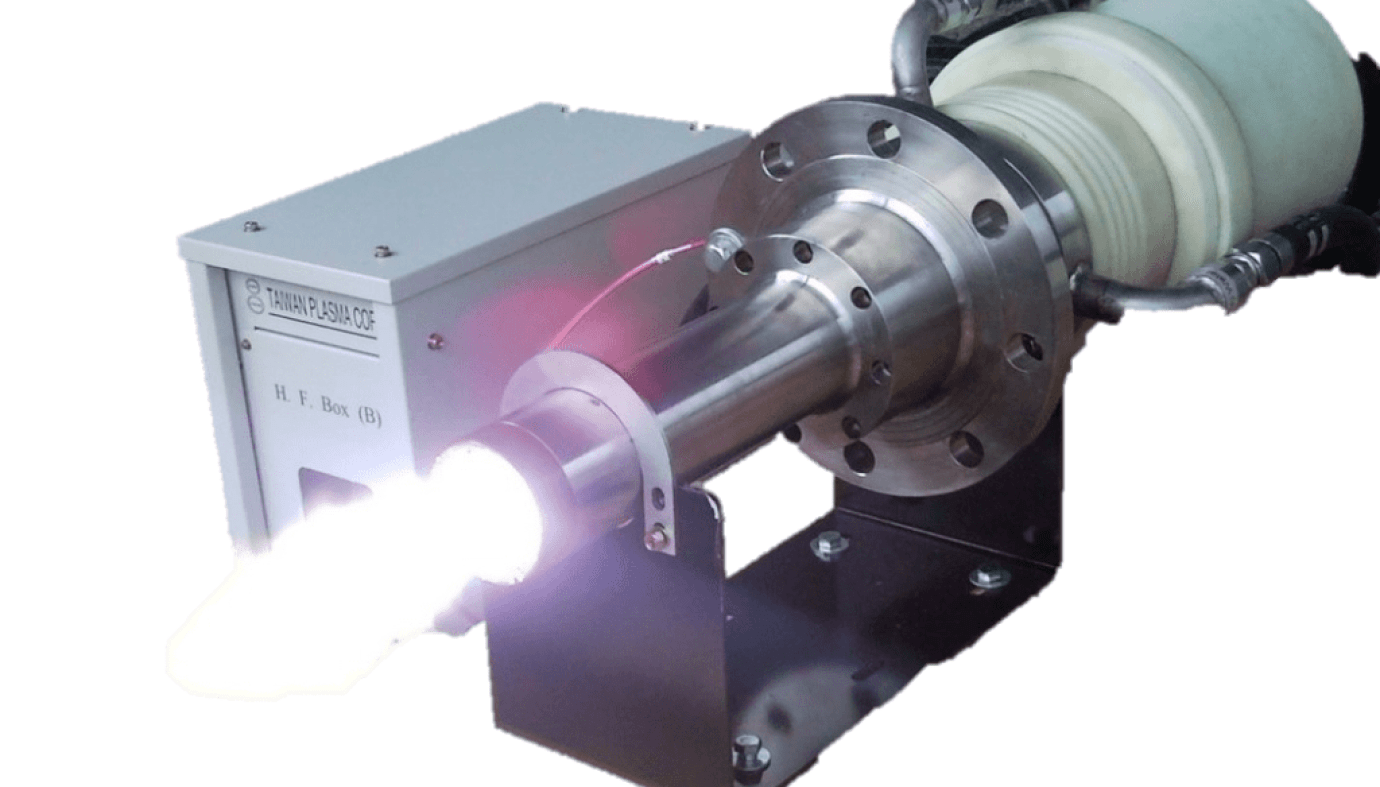

- CNC plasma cutters: CNC plasma cutters are used to cut metal with a hot plasma arc. This is a powerful tool that can be used for a variety of applications in the energy sector, such as the cutting of pipes and shafts.

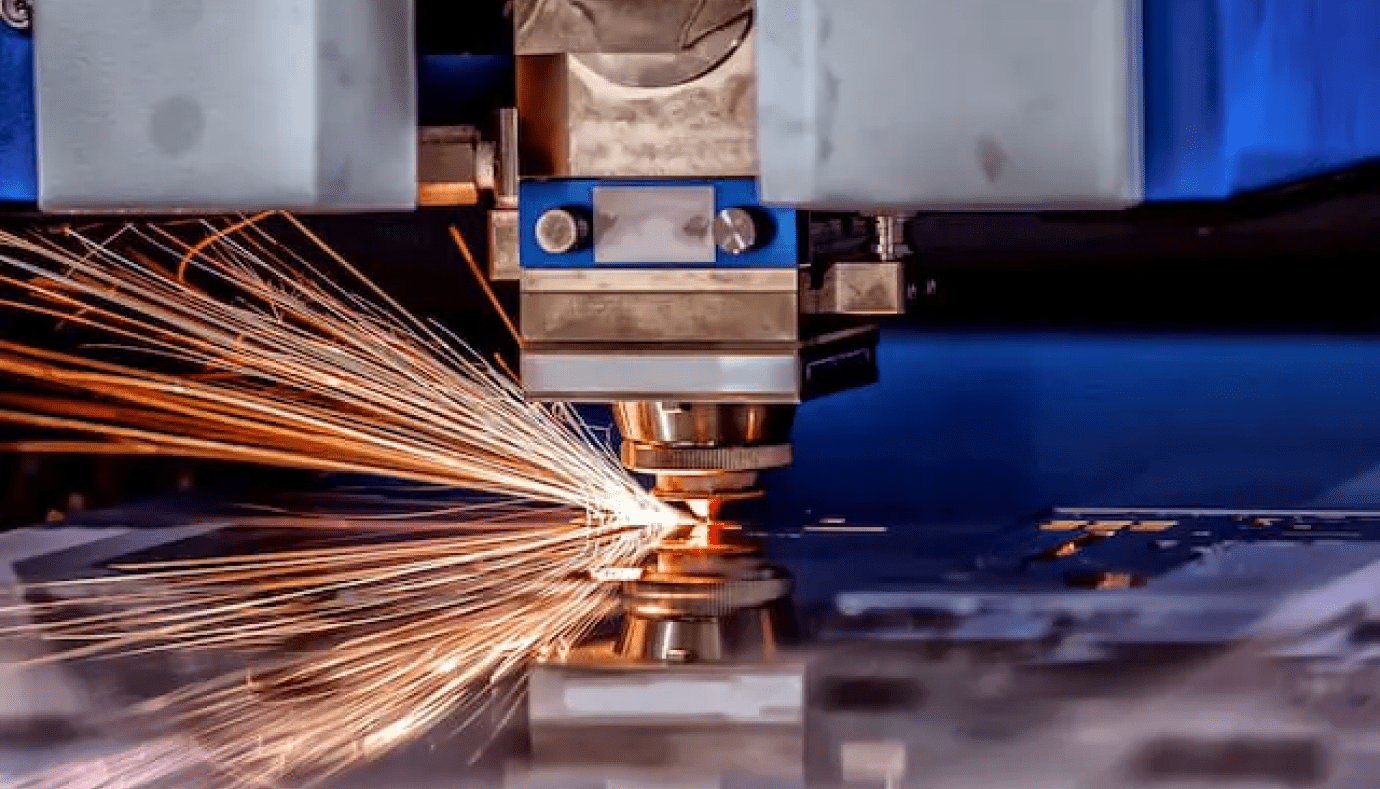

- CNC laser cutters: CNC laser cutters are used to cut metal, plastics, and other materials with a laser beam. This is a precise tool that can be used for a variety of applications in the energy sector, such as the cutting of turbine blades and generator rotors.

CNC machines are an essential part of the pharmaceutical manufacturing process. They help to ensure that pharmaceutical products are produced consistently and accurately.

CNC bending machines: CNC bending machines are used to bend metal sheets and plates. This is a common process in the energy sector, as it is used to manufacture a variety of components, such as heat exchangers, boiler tubes, and wind turbine blades.

- CNC punching machines: CNC punching machines are used to punch holes in metal sheets and plates. This is a common process in the energy sector, as it is used to manufacture a variety of components, such as filter screens, electrical panels, and solar panel frames.

- CNC welding machines: CNC welding machines are used to weld metal parts together. This is a critical process in the energy sector, as it is used to manufacture a variety of components, such as pressure vessels, pipelines, and structural steel.

- CNC EDM machines: CNC EDM machines are used to cut and shape metal by using electrical discharge machining (EDM). EDM is a precision machining process that is often used to manufacture components with complex features or that require tight tolerances.

- CNC wire EDM machines: CNC wire EDM machines are a type of CNC EDM machine that uses a thin wire to cut and shape metal. Wire EDM machines are often used to manufacture components with very tight tolerances.

CNC machines are essential for the manufacturing of components used in power plants, wind turbines, and other energy-related equipment. CNC machines help to ensure that these components are manufactured to precise tolerances, which is critical for the safe and efficient operation of energy systems.

Services We Served In Pharmaceutical Industry

- CNC milling machines

- CNC lathes

- CNC grinders

- CNC water jet cutters

- CNC plasma cutters

- CNC laser cutters

- CNC bending machines

- CNC punching machines

- CNC welding machines

- CNC EDM machines

- CNC wire EDM machines