Finishing Processes

Precision Perfected: Advanced Finishing Processes for Machined Components

Finishing Services offered

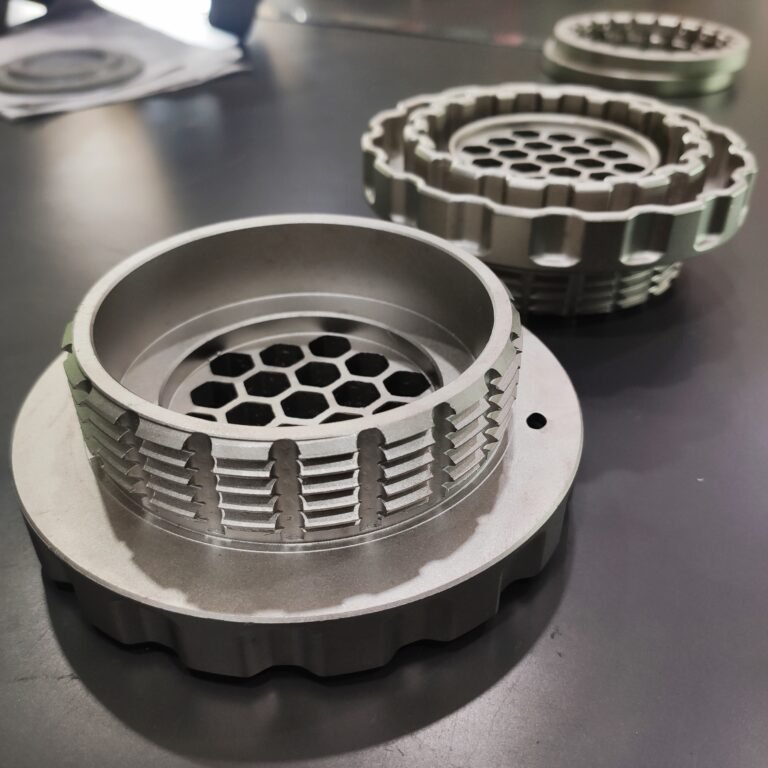

Finishing processes for machined components involve various techniques to refine and enhance the surface quality, dimensional accuracy, and overall appearance of parts produced through machining operations. These processes are critical in achieving the desired specifications and functionality of the final product.

Finish products are typically made from metal, plastic, or wood. They are machined on CNC machines using a variety of tools, such as drills, mills, and lathes. The specific tools and processes used to machine a finished product will vary depending on the material and the desired specifications.

Once a finished product has been machined, it may require additional finishing operations, such as grinding, polishing, or painting. These operations are performed to improve the appearance and performance of the finished product.

Finish product in the CNC industry presented in point form:

Design and CAD/CAM Integration:

- CAD software creates digital models of components.

- CAM software translates designs into machine-readable G-codes.

Material Selection:

- Diverse materials like metals, plastics, composites, and wood are used.

- The material choice affects component properties and performance.

CNC Machining Processes:

- Milling: Rotary cutters remove material for complex shapes.

- Turning: Rotating the workpiece with a cutting tool creates cylindrical components.

- Drilling: Creates holes in the workpiece.

- Grinding: Achieves high precision and surface finish with an abrasive wheel.

- EDM: Uses electrical sparks for intricate shapes and hard metals.

CNC Manufacturing Workflow:

- Preparation: Design, CAM integration, and material selection.

- Setup: Securing workpiece, loading tools, and setting parameters.

- Execution: CNC machine follows G-codes for material removal.

- Quality Control: Sensors and CMMs ensure dimensional accuracy.

- Finishing: Post-processing for enhanced appearance and performance.

Quality Control and Inspection:

- CNC machines are equipped with sensors and probes for real-time adjustments.

- A thorough inspection using CMMs and metrology tools.

Customization and Personalization:

- CNC allows mass customization for individual customer requirements.

- Components tailored to diverse applications and industries.

Automation and Industry 4.0 Integration:

- CNC industry adopts automation and IoT for real-time monitoring.

- Industry 4.0 principles optimize production processes.

Sustainability and Green Manufacturing:

- The CNC industry adopts eco-friendly practices like recycling and energy optimization.

- Focus on reducing environmental footprint.

Advancements in CNC Technology:

- High-speed machining and multi-axis capabilities enhance productivity.

- Hybrid manufacturing (CNC with 3D printing) expands possibilities.

Future Prospects:

- Advancing CNC technology for increased versatility and cost-effectiveness.

- Integration of AI and automation to revolutionize manufacturing.

- Customization options to expand, shaping various industries.

The CNC industry’s finished product results from precise design, advanced CNC machining processes, and rigorous quality control. As technology continues to advance, CNC’s role in customization, sustainability, and automation will shape its future, enabling even greater contributions to industries and global innovation.

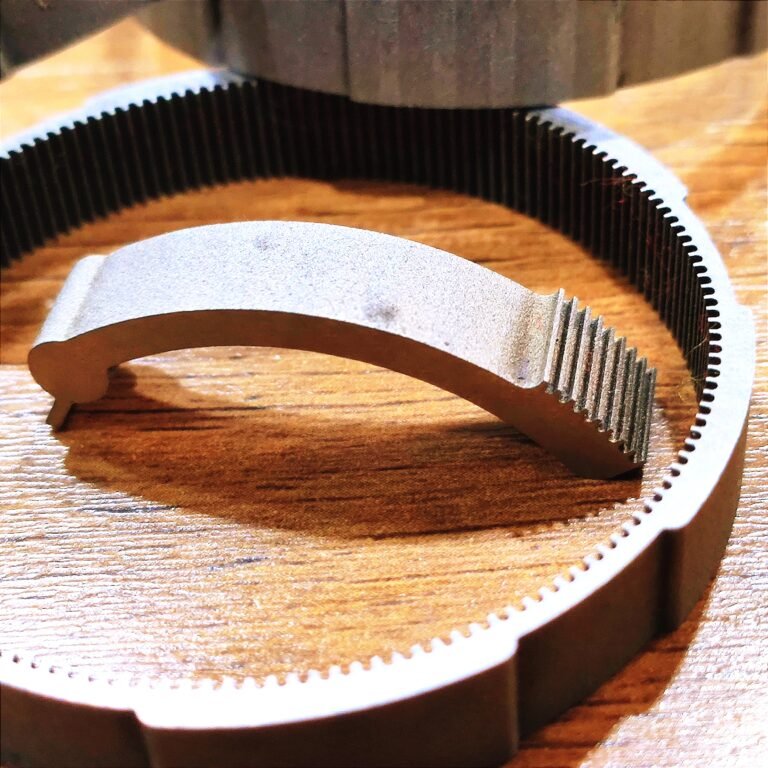

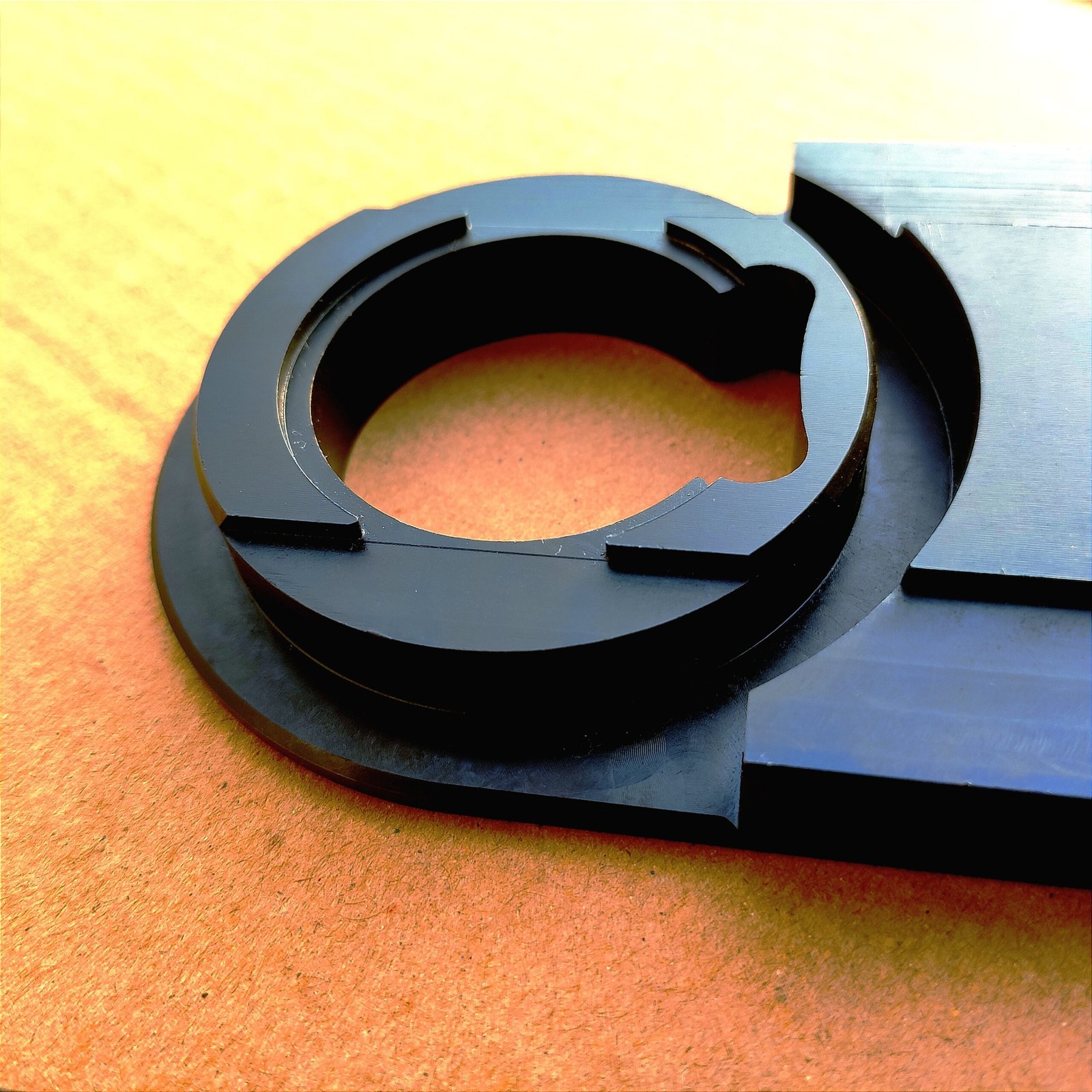

GRINDING & BLASTING

Upon completion of the CNC machining process at Shiv CNC, each machined part emerges with a distinctive texture and visible machining marks. While this inherent texture may be acceptable in some cases, there are instances where it needs refinement or removal to align with the intended application. Achieving the precise appearance of the final product necessitates a meticulous finishing process, marking the concluding steps before the prototype transforms into a tangible reality.

Our in-house facility is equipped to deliver top-tier post-finishing services, catering to various needs. The array of finishing techniques includes Abrasive Blasting, Sand Blasting, Burnishing, Vibratory Finishing, Polishing, and Buffing. Additionally, we offer grinding services to meet specific customer requirements, ensuring the precision assembly of parts.

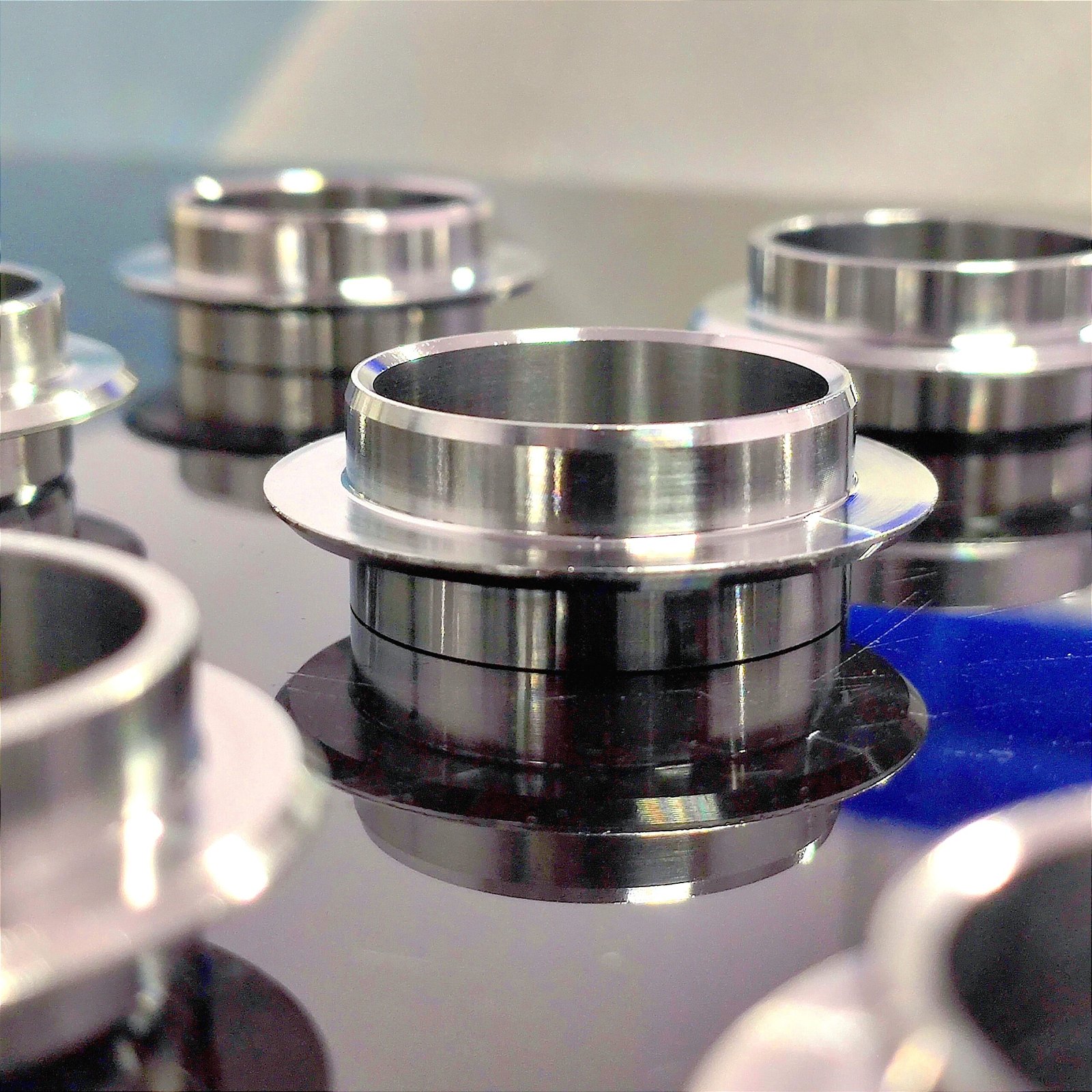

SURFACE TREATMENTS

Surface treatment plays a pivotal role in enhancing the properties of materials, imparting improvements such as increased resistance to corrosion or wear. At Shiv CNC, we prioritize the application of advanced surface treatment processes to elevate the quality and performance of precision parts.

Our commitment to excellence is evident in our utilization of surface treatment techniques such as Aluminum Anodizing(Hard,Soft,Color),Black Oxidization,Chrome Plating, Hot Dip Galvanizing,Zinc Passivation,Electroless Nickel Plating and Electropolishing,These processes not only enhance the aesthetics of the components but also contribute to their durability and functionality. By incorporating these treatments into our manufacturing processes, we ensure that the final products meet and exceed industry standards, providing our customers with reliable and high-performing components.

We also offer MIL-DTL-5541 Chemical Conversion Coating,

POWDER COATING AND PAINTING

At Shiv CNC, we employ the widely recognized RAL classic system as our go-to method for matching custom-blended paints to any specified color code or paint swatch. Our expertise lies in achieving precise color formulations to meet your unique requirements.

For projects involving two-color or multi-color painting, we implement meticulous masking techniques. This involves the strategic use of tape and proper masks to ensure tight and clean mask lines. This attention to detail allows us to seamlessly divide elements of your monolithic prototype, enabling the application of multiple finishes for a more intricate appearance reminiscent of 2k and 3k molding.

LASER MARKING ,ENGRAVING AND ETCHING

Completed parts can be customized to the next level through our precision laser marking and engraving services, particularly for metal items. Our commitment to quality work ensures that your CNC machined parts receive impeccable laser marking and engraving, adding a distinctive touch to each item.

Elevate the identity of your CNC machined parts with the artistry of laser marking and engraving, showcasing the dedication to craftsmanship that defines Shiv CNC.