Tool & Die Makers

Shivay Enterprise provides preventive, predictive, and corrective maintenance to keep CNC machines in top condition for mission-critical operations.

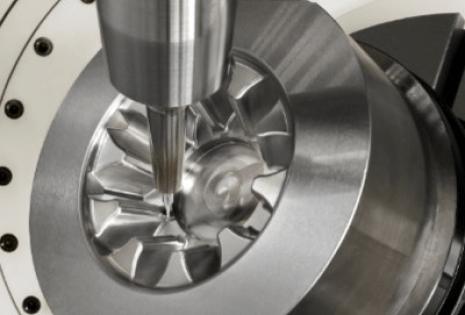

Tool & Diemakers CNC machine servicing experts

We use state-of-the-art equipment and techniques to ensure that your CNC machines are always in top condition.

Shivay Enterprise is committed to helping its customers keep their tool maker CNC machines and die maker machines running smoothly and efficiently. They offer a wide range of maintenance servicing services to help you meet your specific needs.

Preventive maintenance: Shivay Enterprise can help you develop a preventive maintenance plan for your tool maker CNC machine and die maker machines. This plan will help you to identify and fix potential problems before they cause downtime.

Corrective maintenance: If your tool maker CNC machine or die maker machine breaks down, Shivay Enterprise can help you to repair it quickly and efficiently. They have a team of experienced technicians who are familiar with the specific needs of these types of machines.

Emergency repairs: If your tool maker CNC machine or die maker machine breaks down unexpectedly, Shivay Enterprise can provide emergency repairs. They have a 24/7 emergency service that is available to help you get your machine back up and running as soon as possible.

- Training: Shivay Enterprise can also provide training for your employees on how to operate and maintain your tool maker CNC machine and die maker machines. This training will help your employees to use the machines safely and efficiently, and it will help to reduce the risk of downtime.

Parts supply: Shivay Enterprise can also supply you with parts for your tool maker CNC machine and die maker machines. This includes both worn parts and replacement parts. Shivay Enterprise has a wide inventory of parts in stock, so they can usually get the parts you need quickly and easily.

Here are some additional details about Shivay Enterprise’s maintenance servicing services for companies who make tool maker CNC machine and die maker machines:

Shivay Enterprise’s preventive maintenance plan will include a schedule of regular checks and inspections. These checks will be performed by Shivay Enterprise’s experienced technicians, who will look for any potential problems with your machines. If any problems are found, Shivay Enterprise will take steps to fix them before they cause downtime.

Shivay Enterprise’s corrective maintenance services are available 24/7. This means that if your machine breaks down unexpectedly, Shivay Enterprise can send a technician to your facility to repair it as soon as possible.

Shivay Enterprise’s training services are tailored to the specific needs of your employees. Shivay Enterprise will work with you to develop a training program that will teach your employees how to operate and maintain your machines safely and efficiently.

Shivay Enterprise’s parts supply services are available 24/7. This means that if you need a part for your machine, Shivay Enterprise can usually get the part you need quickly and easily.

Here are some of the benefits of working with Shivay Enterprise for your CNC machine maintenance and servicing needs :

Increased uptime: By working with Shivay Enterprise, you can help to ensure that your CNC machine is always up and running. This will help you to avoid lost production time and keep your business running smoothly.

Improved quality: Shivay Enterprise can help you to improve the quality of your products by ensuring that your CNC machine is properly maintained and calibrated. This will help you to produce high-quality products that meet your customers’ expectations.

Reduced costs: By working with Shivay Enterprise, you can help to reduce the cost of owning and operating your CNC machine. This is because Shivay Enterprise can help you to identify and fix potential problems before they cause costly repairs.

- Increased safety: Shivay Enterprise can help you to improve the safety of your CNC machine operation by providing training to your employees and ensuring that your machine is properly maintained. This will help to protect your employees and your business from accidents.

- Peace of mind: By working with Shivay Enterprise, you can have peace of mind knowing that your CNC machine is in good hands. Shivay Enterprise is committed to providing its customers with timely and efficient service, so you can be confident that your machine will be back up and running as soon as possible if it breaks down.

Here are some machines who servicing by Shivay Enterprise in Tool & Die-makers sector :

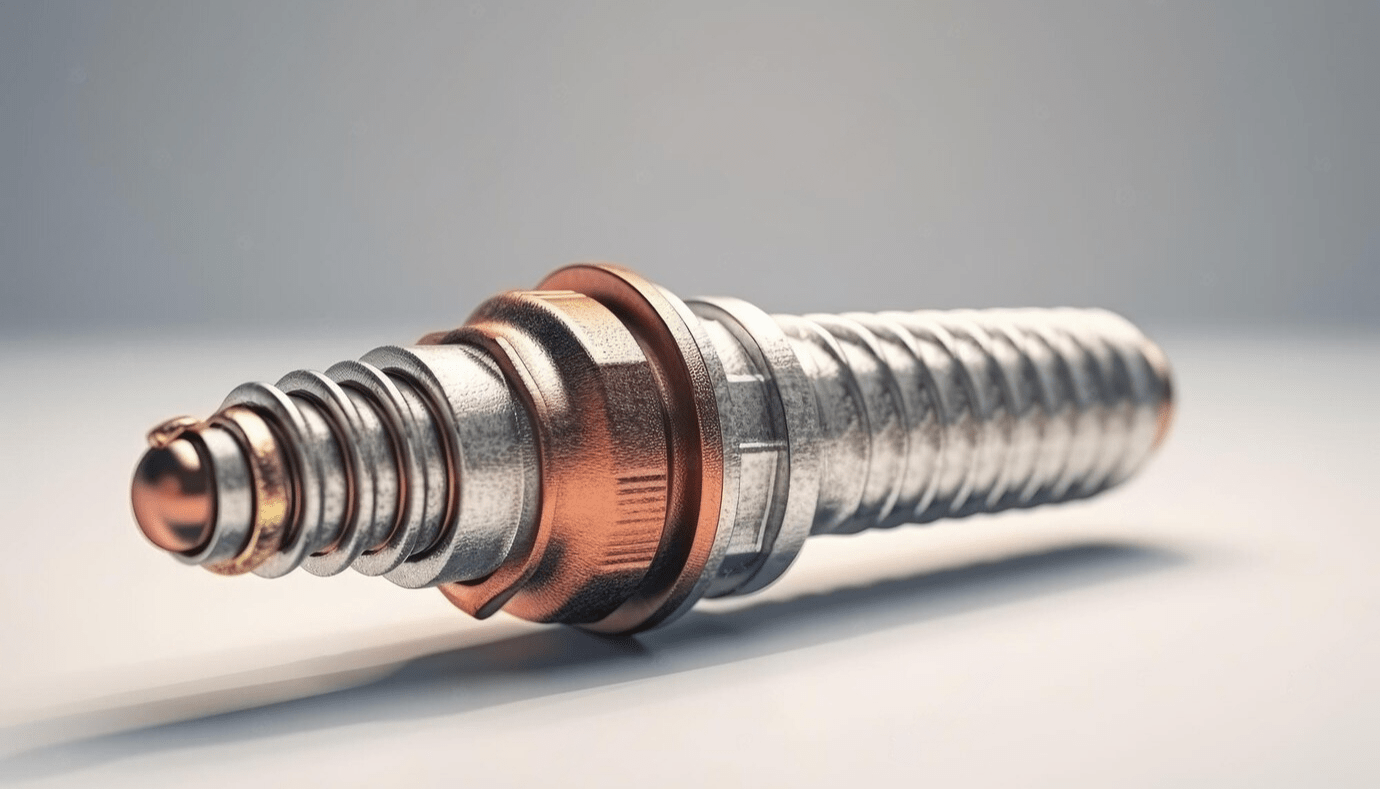

CNC Lathes: CNC lathes are used to turn metal blanks into precision parts. They are very versatile machines and can be used to produce a wide variety of parts, including shafts, gears, and bearings. CNC lathes use a rotating spindle to turn the workpiece while a cutting tool is used to remove material. The cutting tool can be moved in a variety of directions, allowing the operator to create complex shapes.

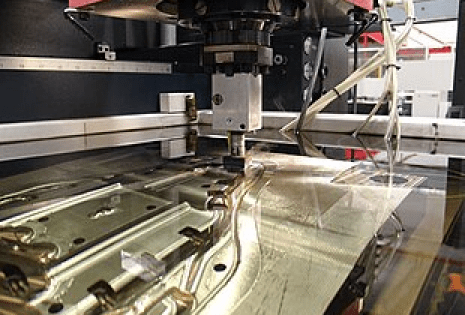

CNC Milling Machines: CNC milling machines are used to cut metal parts from solid stock. They are more powerful than CNC lathes and can be used to produce larger parts with more complex features. CNC milling machines use a rotating spindle to hold the cutting tool, which is then moved in a variety of directions to cut the workpiece. CNC milling machines can be used to create a wide variety of shapes, including slots, holes, and contours.

CNC Grinding Machines: CNC grinding machines are used to finish metal parts with a high degree of accuracy. They are often used to grind the surfaces of parts that have been machined on other machines, such as CNC lathes and CNC milling machines. CNC grinding machines use a rotating grinding wheel to remove material from the workpiece. The grinding wheel can be moved in a variety of directions, allowing the operator to create a smooth, even surface.

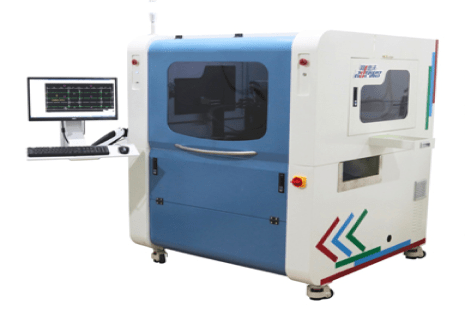

CNC EDM Machines: CNC EDM machines are used to machine metal parts by using a high-voltage electric spark to erode the workpiece. They are often used to machine parts that are difficult or impossible to machine with traditional methods, such as hardened steel and titanium. CNC EDM machines use a high-voltage spark to create a small hole in the workpiece. The hole is then enlarged by moving the spark around the workpiece. This process can be repeated to create complex shapes in the workpiece.

Accuracy: CNC machines used in the tool & die-maker industry require a high degree of accuracy. This is because the parts they produce are used to make other machines, which must also be very precise.

Durability: CNC machines used in the tool & die-maker industry must be durable. This is because they are often used to machine hard materials, such as steel and titanium.

Complexity: CNC machines used in the tool & die-maker industry can be very complex. This is because they often need to be able to machine a variety of different parts.

Size: CNC machines used in the tool & die-maker industry can be larger than CNC machines used in other industries. This is because they often need to be able to machine large parts.

Cost: CNC machines used in the tool & die-maker industry can be more expensive than CNC machines used in other industries. This is because they are more complex and require higher precision.

These are just a few of the machines that are used in tools & die-maker industry. The specific type of machine that is used will depend on the specific application.

- Proper maintenance procedures: This includes tasks such as regularly inspecting the machine for wear and tear, lubricating the moving parts, and cleaning the machine to prevent the buildup of dirt and debris.

- The right type of CNC machine: The type of CNC machine that you need will depend on the specific application. For example, if you need to machine large parts, you will need a CNC machine with a larger worktable.

- Longevity: CNC machines can last for many years with proper maintenance. By following the maintenance procedures outlined in your CNC machine’s manual, you can help to extend the life of your machine.

- Performance: CNC machines that are properly maintained will perform better than machines that are not. This is because the machine will be able to operate at its full potential without any disruptions.

By following these maintenance procedures, you can help to ensure that your CNC machine is in good working condition and that it will continue to produce high-quality parts for many years to come.

Services We Served In Tool & Die-maker Industry

- CNC lathes

- CNC grinders

- CNC EDM machines

- CNC wire EDM machines

- CNC laser cutters

- CNC plasma cutters