Pharmaceutical

Shivay Enterprise: CNC machine maintenance that’s safe and compliant with Food industry regulations.

Pharmaceutical industry CNC machine servicing experts

CNC machine maintenance service provider for the Pharmaceutical industry.

CNC machine maintenance is essential for keeping CNC machines running smoothly and efficiently in the pharmaceutical industry. It helps to prevent breakdowns, extend the lifespan of machines, and improve the quality of products produced. Shivay Enterprise is a CNC machine maintenance service provider that specializes in the pharmaceutical industry. They have a team of experienced engineers who are familiar with the specific needs of this industry. Shivay Enterprise offers a variety of CNC machine maintenance services, including preventive maintenance, corrective maintenance, installation and commissioning, and training.

Shivay Enterprise is a CNC machine maintenance company that specializes in the pharmaceutical industry. They offer a comprehensive range of maintenance services to keep your CNC machines running smoothly and efficiently. This includes preventive maintenance, corrective maintenance, installation and commissioning, and training.

Shivay Enterprise has a team of experienced engineers who are familiar with the specific needs of the pharmaceutical industry. They use state-of-the-art equipment and tools to ensure that your CNC machines are properly maintained and repaired. They are also committed to safety and use safe and compliant procedures for all maintenance activities.

- Peace of mind: Knowing that your CNC machines are being properly maintained by experienced engineers can give you peace of mind. This can help you to focus on your core business activities, knowing that your machines are in good hands.

- Increased uptime: Preventive maintenance can help to prevent breakdowns, which can lead to increased uptime for your CNC machines. This can help you to reduce costs and improve productivity.

- Improved quality: Properly maintained CNC machines can produce higher-quality products. This can help you to meet the quality standards required by your customers.

- Reduced costs: Preventive maintenance can help to reduce costs by preventing breakdowns and extending the lifespan of your CNC machines.

If you are in a pharmaceutical business that is looking for a reliable and experienced CNC machine maintenance company, then Shivay Enterprise is the perfect choice for you. Contact them today to learn more about their services and how they can help you to keep your CNC machines running smoothly and efficiently.

Here are some additional details about Shivay Enterprise’s for pharmaceutical industry :

Preventive Maintenance

CNC machines are essential for the pharmaceutical industry. They are used to produce a wide range of products, from tablets and capsules to needles and syringes. CNC machines are highly specialized and require regular maintenance to ensure that they operate at peak performance. Shivay Enterprise is a CNC machine maintenance company that specializes in the pharmaceutical industry. They offer a comprehensive range of maintenance services to keep your CNC machines running smoothly and efficiently.

Corrective Maintenance

Corrective maintenance is the process of repairing CNC machines that have broken down. Shivay Enterprise engineers can repair CNC machines quickly and efficiently, using state-of-the-art equipment and tools. They will diagnose the problem and repair the machine using the correct parts and techniques. This will help to get your machine back up and running as quickly as possible.

Installation and Commissioning

Shivay Enterprise can also install and commission CNC machines for businesses in the pharmaceutical industry. This includes setting up the machine, loading the software, and training employees on how to operate it. Shivay Enterprise will work with you to understand your specific needs and requirements. They will then install and commission your CNC machine according to your specifications.

Training

Shivay Enterprise also offers training on how to operate and maintain CNC machines. This training is tailored to the specific needs of your business. Shivay Enterprise engineers will provide classroom training on the basics of CNC machine operation and maintenance. They will also provide on-the-job training to employees on how to operate the specific CNC machines that are used in your business. This training will help to ensure that your employees are able to operate your CNC machines safely and efficiently.

Advantages of Using Shivay Enterprise

There are many advantages to using Shivay Enterprise for CNC machine maintenance in the pharmaceutical industry. These include:

- Experienced engineers: Shivay Enterprise has a team of experienced engineers who are familiar with the specific needs of the pharmaceutical industry. They have the knowledge and skills to keep your CNC machines running smoothly and efficiently.

- State-of-the-art equipment: Shivay Enterprise uses state-of-the-art equipment and tools to ensure that your CNC machines are properly maintained and repaired. This equipment allows them to perform maintenance quickly and efficiently, with minimal downtime.

- Commitment to safety: Shivay Enterprise is committed to safety. They use safe and compliant procedures for all maintenance activities. This helps to protect your employees and equipment.

- Flexible scheduling: Shivay Enterprise can accommodate a variety of scheduling needs. They can provide maintenance on a regular basis or on an as-needed basis. This allows you to get the maintenance you need when you need it.

- Competitive pricing: Shivay Enterprise offers competitive pricing on all of its CNC machine maintenance services. This means that you can get the peace of mind that comes with knowing that your CNC machines are being properly maintained without breaking the bank.

Types of CNC Machines Used in pharmaceutical industry

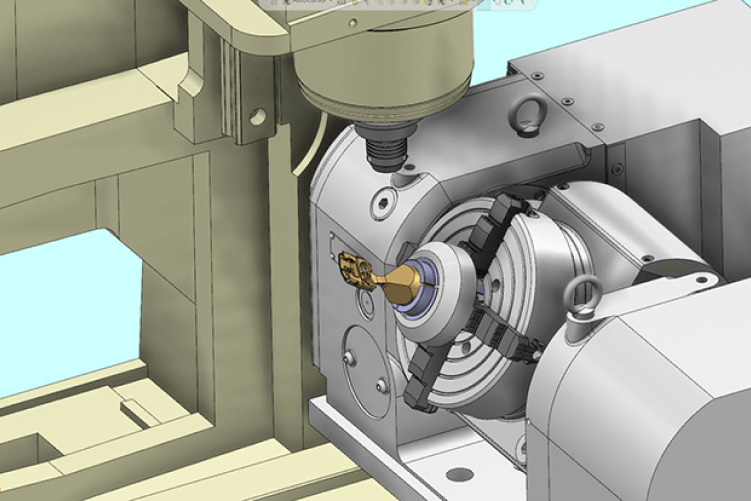

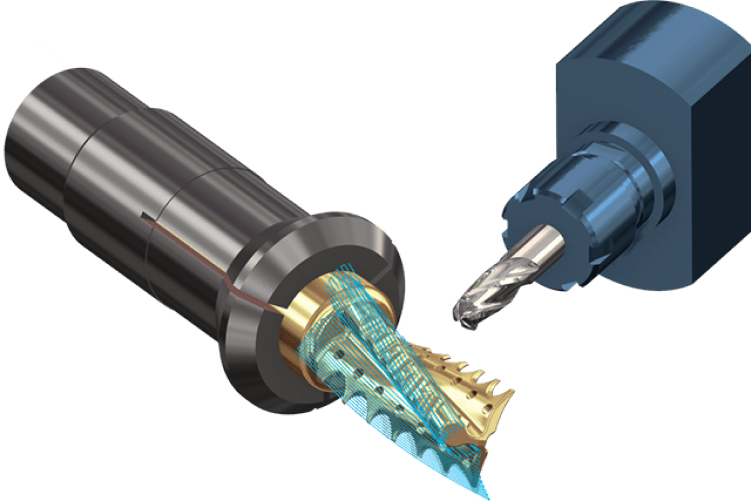

CNC milling machines: CNC milling machines are used to create complex parts with high precision. They are used to produce a wide range of parts for pharmaceutical equipment, such as molds, dies, and other precision parts. For example, CNC milling machines can be used to create molds for pharmaceutical tablets and capsules.

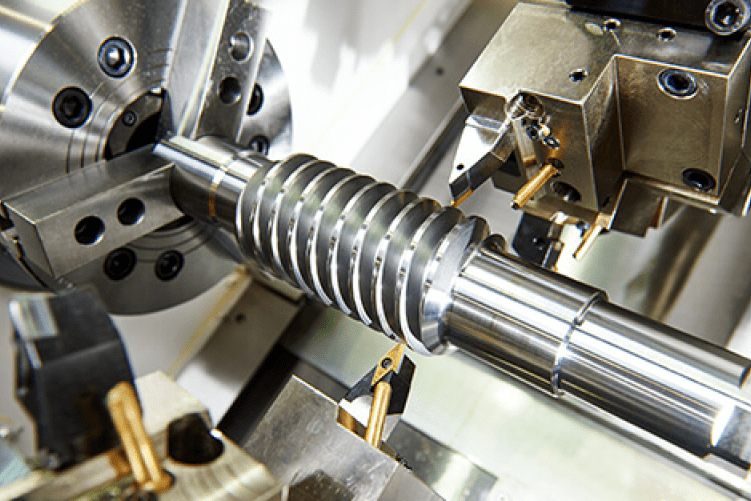

CNC turning machines: CNC turning machines are used to create cylindrical parts with high precision. They are used to produce a variety of parts, such as shafts, axles, and bearings. For example, CNC turning machines can be used to create shafts for pharmaceutical pumps.

CNC wire EDM machines: CNC wire EDM machines are used to create very precise parts with complex geometries. They are used to produce dies and molds for pharmaceutical products. For example, CNC wire EDM machines can be used to create the dies for pharmaceutical capsules.

CNC laser cutting machines: CNC laser cutting machines are used to cut a variety of materials, including metal, plastic, and glass. They are used to produce a wide range of parts for pharmaceutical equipment, such as packaging and labels. For example, CNC laser cutting machines can be used to cut the plastic strips that hold pharmaceutical tablets together.

CNC 5-axis milling machines: CNC 5-axis milling machines are used to create complex parts with high precision. They can mill a workpiece from five different axes, which allows for the creation of parts that would not be possible with a 3-axis machine. For example, CNC 5-axis milling machines can be used to create the dies for pharmaceutical vials.

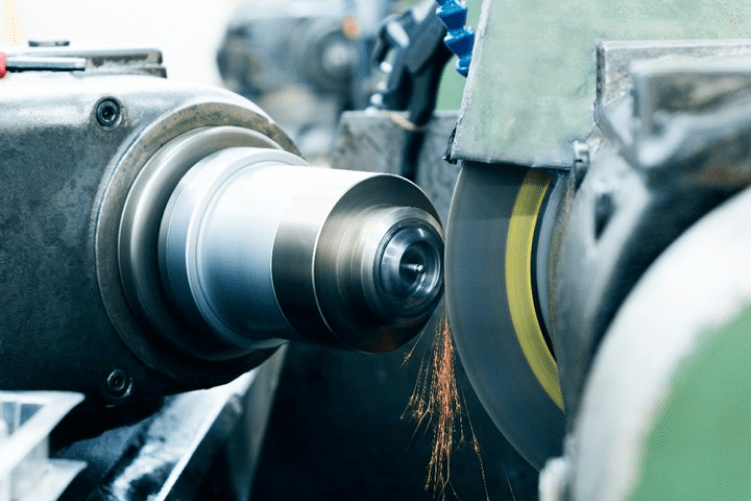

CNC grinding machines: CNC grinding machines are used to remove material from a workpiece by using abrasive wheels. They are used to create very precise parts, such as those used in dies and molds. For example, CNC grinding machines can be used to grind the dies for pharmaceutical tablets.

CNC machines are an essential part of the pharmaceutical manufacturing process. They help to ensure that pharmaceutical products are produced consistently and accurately.

CNC lathes: CNC lathes are used to rotate the workpiece while a cutting tool moves along the axis of rotation. This allows for the creation of cylindrical parts, such as shafts, tubes, and axles. For example, CNC lathes can be used to create shafts for pharmaceutical pumps.

CNC plasma cutting machines: CNC plasma cutting machines use a plasma arc to cut metal. Plasma cutting is a fast and precise process that can be used to cut a variety of metals, including steel, aluminum, and stainless steel. For example, CNC plasma cutting machines can be used to cut the metal sheets that are used to make pharmaceutical packaging.

CNC EDM machines: CNC EDM machines use electrical discharge machining to cut metal. EDM is a process that uses electric sparks to erode the workpiece. This is a very precise process that can be used to cut very intricate shapes. For example, CNC EDM machines can be used to cut the metal molds that are used to make pharmaceutical tablets.

CNC waterjet cutting machines: CNC waterjet cutting machines use a high-pressure water jet to cut material. Waterjet cutting is a fast and precise process that can be used to cut a variety of materials, including metal, plastic, and glass. For example, CNC waterjet cutting machines can be used to cut the plastic sheets that are used to make pharmaceutical packaging.

Services We Served In Pharmaceutical Industry

- CNC milling machines

- CNC turning machines

- CNC wire EDM machines

- CNC laser-cutting machines

- CNC 5-axis milling machines

- CNC grinding machines

- CNC lathes

- CNC plasma-cutting machines

- CNC EDM machines

- CNC waterjet cutting machines