CNC Lathes Turning

Shivay Enterprise: Turning your visions into reality with precision CNC machining and the latest innovative technologies.

CNC Lathes Turning Services

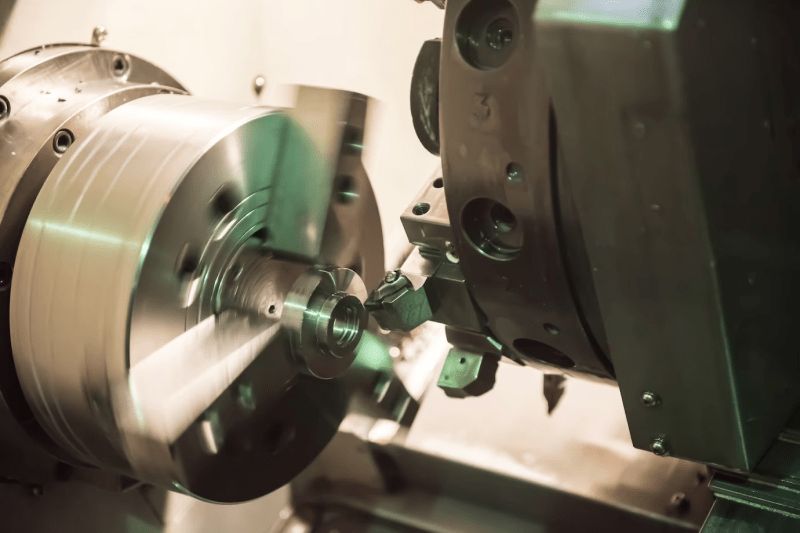

What is Lathes Turning Services ?

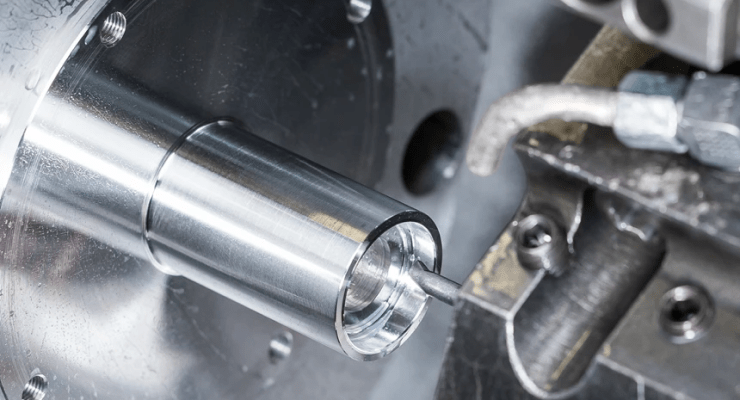

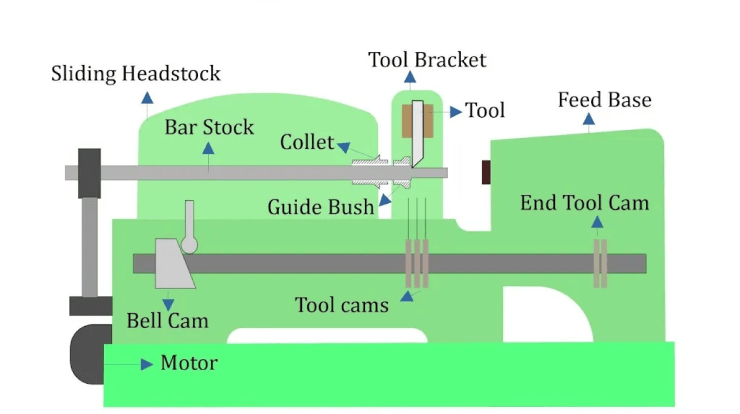

Lathe turning is a machining process that uses a lathe to create cylindrical parts. The lathe is a machine tool that holds the workpiece in place and rotates it while a cutting tool is used to shape the workpiece.

Lathe turning is a versatile process that can be used to create a wide variety of parts, including shafts, rods, tubes, and other cylindrical parts. It is also a very precise process, which makes it ideal for creating parts with tight tolerances.

There are two main types of lathe turning: conventional lathe turning and CNC lathe turning. Conventional lathe turning is a manual process that requires the operator to manually control the cutting tool. This type of lathe turning is less precise than CNC lathe turning, but it is also less expensive.

CNC lathe turning is a computer-controlled process that uses a computer to control the cutting tool. This type of lathe turning is more precise than conventional lathe turning, but it is also more expensive.

Types of Lathes Turning :

There are two main types of lathe turning: conventional lathe turning and CNC lathe turning.

Conventional lathe turning is a manual process that requires the operator to manually control the cutting tool. This type of lathe turning is less precise than CNC lathe turning, but it is also less expensive.

- CNC lathe turning is a computer-controlled process that uses a computer to control the cutting tool. This type of lathe turning is more precise than conventional lathe turning, but it is also more expensive.

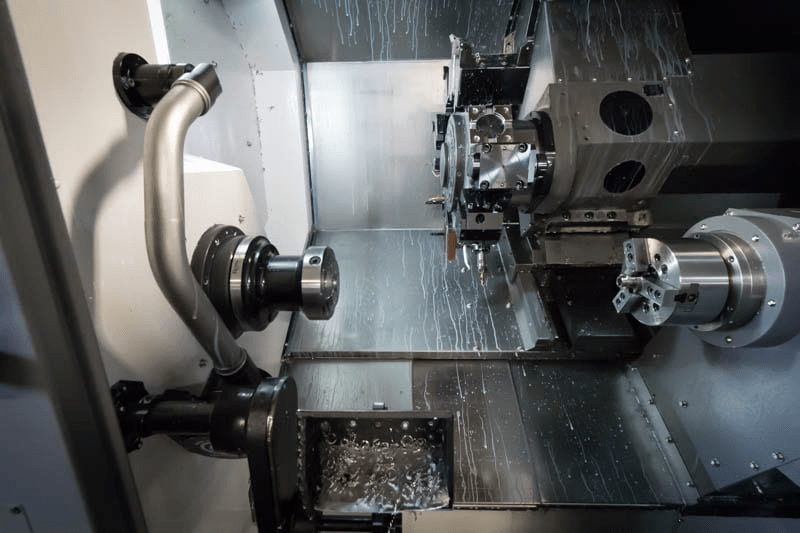

Process of Lathes Turning :

- Setup: The first step in lathe turning is to set up the lathe. This includes mounting the workpiece on the lathe and adjusting the cutting tool.

- Roughing: The second step in lathe turning is to rough out the shape of the workpiece. This is done using a coarse cutting tool to remove a large amount of material from the workpiece.

- Finishing: The third step in lathe turning is to finish the shape of the workpiece. This is done using a fine-cutting tool to remove a small amount of material from the workpiece.

- Deburring: The final step in lathe turning is to deburr the workpiece. This is done to remove any sharp edges or burrs from the workpiece.

Future of LathesTurning :

- Increased demand for precision parts: CNC lathes can be used to create parts with very tight tolerances. This makes them ideal for applications where precision is critical, such as the aerospace and medical industries.

- Development of new materials: The development of new materials, such as composites and ceramics, has created a need for new machining processes that can be used to machine these materials. CNC lathes are well-suited for machining these materials due to their precision and versatility.

- Advances in automation: Advances in automation are making CNC lathes more efficient and easier to use. This is making them more accessible to small businesses and manufacturers who do not have the resources to invest in traditional lathes.

- The use of artificial intelligence (AI): AI is being used to develop new CNC lathes that can learn and adapt to their environment. This will allow CNC lathes to be more efficient and accurate, and it will also make them easier to use.

- The use of cloud-based manufacturing: Cloud-based manufacturing is a new trend that is gaining popularity. This allows manufacturers to access CNC lathes and other manufacturing equipment remotely. This can make it easier for manufacturers to produce parts, and it can also reduce the cost of manufacturing.

- The use of 5-axis CNC lathes: 5-axis CNC lathes are capable of machining parts in 5 dimensions. This allows them to create parts with complex geometries that would be difficult or impossible to create with traditional CNC lathes.

These are just a few of the trends that are expected to shape the future of lathe turning in CNC machining. As these trends continue to develop, CNC lathes will become even more versatile and precise. This will make them even more valuable to manufacturers in a wide variety of industries.

Overall, the future of lathe turning in CNC machining is bright. The use of CNC lathes is expected to grow in the future due to the increasing demand for precision parts, the development of new materials, and advances in automation.

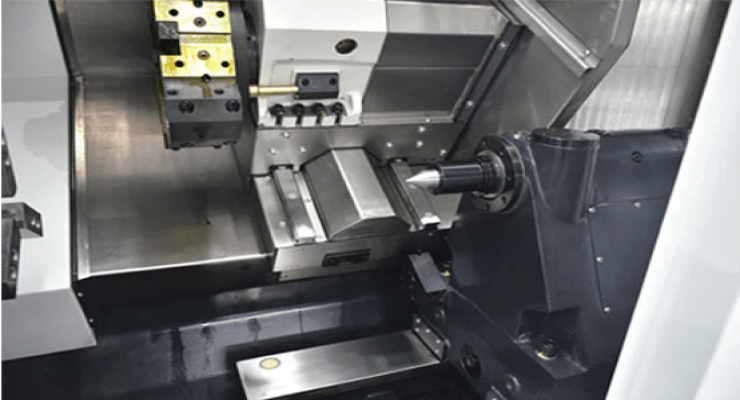

Here are some of the benefits of using lathes turning machines :

- Precision: Lathe-turning machines can create parts with very tight tolerances. This is critical for applications where precision is essential, such as the aerospace and medical industries.

- Versatility: Lathe turning machines can be used to machine a wide variety of materials and parts. This makes them a versatile tool for manufacturers.

- Speed: Lathe turning machines can produce parts quickly and efficiently. This can save manufacturers money on labor and materials.

- Accuracy: Lathe turning machines can produce parts with consistently high accuracy. This is important for manufacturers who need to meet strict quality standards.

- Durability: Lathe turning machines are built to last. They can withstand the rigors of production environments and provide years of reliable service.

- Cost-effectiveness: Lathe turning machines are a cost-effective way to produce parts. They can save manufacturers money on labor, materials, and time.

- Ease of use: Lathe turning machines are relatively easy to use. They can be operated by skilled operators or by trained machine operators.

How Shivay Enterprise is different from other Sink/RAM EDM machining service companies:

- We have a team of highly skilled and experienced machinists. Our machinists are experts in CNC machining, and they are committed to producing high-quality parts.

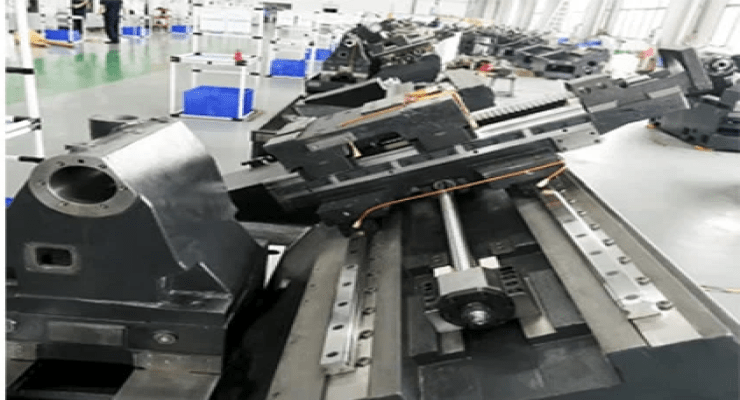

- We have a state-of-the-art CNC lathe machine park. Our machines are some of the most advanced in the industry, and they allow us to produce parts with very precise tolerances.

- We have a strict quality control system in place. Our quality control system ensures that all of our parts meet our high standards.

- We are committed to customer satisfaction. We are always available to answer our customers’ questions and to help them meet their needs.

- We offer a wide range of services. We can turn a wide variety of materials, and we can perform a variety of operations.

- We are flexible and responsive to our customers’ needs. We can accommodate a wide range of customer requirements, including short lead times and custom parts.

- We offer competitive prices. We are committed to providing our customers with the best possible value for their money.

- We are located in India. This gives us a competitive advantage in terms of cost and time.

- We are a family-owned and operated business. This means that we are committed to providing our customers with the best possible service.

Lathe-turning machining service is used in a wide variety of applications, including:

- Aerospace: Lathe-turning machines are used to produce precision parts for aircraft engines, landing gear, and other critical components. For example, lathe-turning machines are used to produce turbine blades for jet engines. These blades need to be very precisely machined in order to operate efficiently and safely.

- Medical: Lathe-turning machines are used to produce medical devices such as implants, surgical tools, and prosthetics. For example, lathe-turning machines are used to produce the screws that are used to hold implants in place. These screws need to be very precisely machined in order to ensure that they are strong enough to hold the implant in place, but not so strong that they damage the surrounding tissue.

- Jewelry: Lathe-turning machines are used to create jewelry, such as rings, necklaces, and earrings. This is a popular process for creating custom jewelry that is unique and one-of-a-kind.

- Tooling: Lathe-turning machines are used to create toolings, such as dies, molds, and gauges. This is a critical process in the manufacturing of a wide variety of products.Prototypes: Lathe turning machines are used to create prototypes, which are early models of products that are used to test and refine designs. This is a valuable process for reducing the risk of costly mistakes in the manufacturing process.

- R&D: Lathe-turning machines are used in research and development (R&D) to create new products and processes. This is a critical process for innovation and growth in the manufacturing industry.

How Shivay Enterprise can help you with Sink/RAM EDM maintenance servicing:

- We offer remote monitoring: We can remotely monitor your lathe-turning machines to identify potential problems before they become major issues. This can help you to save time and money in the long run.

- We offer predictive maintenance: We can use data from our remote monitoring system to predict when your lathe turning machines need maintenance. This can help you to schedule maintenance at a time that is convenient for you and to avoid unexpected downtime.

- We offer 24/7 support: We offer 24/7 support in case you have any problems with your lathe-turning machines. This means that you can always get help when you need it, even if it is in the middle of the night.

- We can help you with custom lathe-turning maintenance plans: We can work with you to develop a custom lathe-turning maintenance plan that meets your specific needs. This means that you can get the exact service you need, without paying for anything you don’t need.

- We can help you with emergency lathe turning maintenance: If you have an emergency lathe turning maintenance need, we can help you get your machines back up and running as quickly as possible. We understand that downtime can be costly, so we will do everything we can to get your machines back up and running as quickly as possible.

- We can help you with lathe turning maintenance training: We can provide training on how to operate and maintain your lathe turning machines. This will help you to ensure that your machines are operated safely and efficiently.

If you are looking for a reliable and affordable lathe-turning maintenance provider that can offer you unique benefits, then Shivay Enterprise is the right choice for you. We have a team of experienced technicians who can help you with all of your lathe-turning maintenance needs. We offer a wide range of services and are competitively priced. Contact us today to learn more about how we can help you.

Lathe-turning in Defence

Lathe-turning can be a very precise way to produce defense components. CNC lathes can be programmed to maintain very tight tolerances, which can help to ensure that the components meet the required specifications.

Lathe-turning can be a very precise way to produce defense components. CNC lathes can be programmed to maintain very tight tolerances, which can help to ensure that the components meet the required specifications.

Lathe-turned components are typically more reliable than components that are made using other processes. This is because lathe-turning can produce components with very tight tolerances, which reduces the risk of failure.

Lathe-turning in Medical

Lathe-turning can be a very precise way to produce medical components. CNC lathes can be programmed to maintain very tight tolerances, which can help to ensure that the components meet the required specifications.

Lathe-turning can be a very precise way to produce medical components. CNC lathes can be programmed to maintain very tight tolerances, which can help to ensure that the components meet the required specifications.

Lathe-turning can be a cost-effective way to produce medical components. CNC lathes can be used to produce small batches of components, which can help to reduce the cost of tooling and setup.

Lathe-turning in Oil & Gas

Lathe-turning can be a very precise way to produce oil and gas components. CNC lathes can be programmed to maintain very tight tolerances, which can help to ensure that the components meet the required specifications.

Lathe-turning can be a cost-effective way to produce oil and gas components. CNC lathes can be used to produce small batches of components, which can help to reduce the cost of tooling and setup.

Lathe-turning is a versatile and efficient process that can be used to produce a variety of oil and gas components with high precision and accuracy.

Lathe-turning in Optic

Lathe-turning is a machining process that uses a lathe to remove material from a rotating workpiece. This process can be used to create a variety of optical components, such as lenses, mirrors, and prisms.

Lathe-turning is a critical process in the manufacturing of optical components. By using a toolroom lathe and high-quality tools and cutting fluids, manufacturers can create optical components with the precision and accuracy required for a variety of applications.