Micromachining Services

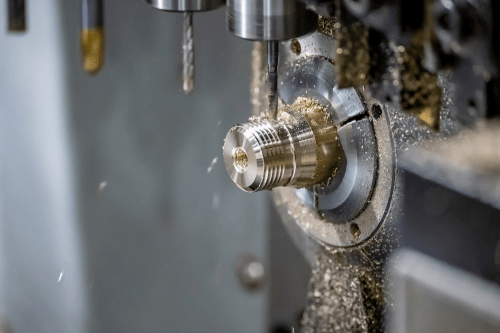

Shiv CNC provides micromachining services that use precision machine tools to create parts with very small dimensions.

Micromachining Services :

What is Micromachining Services ?

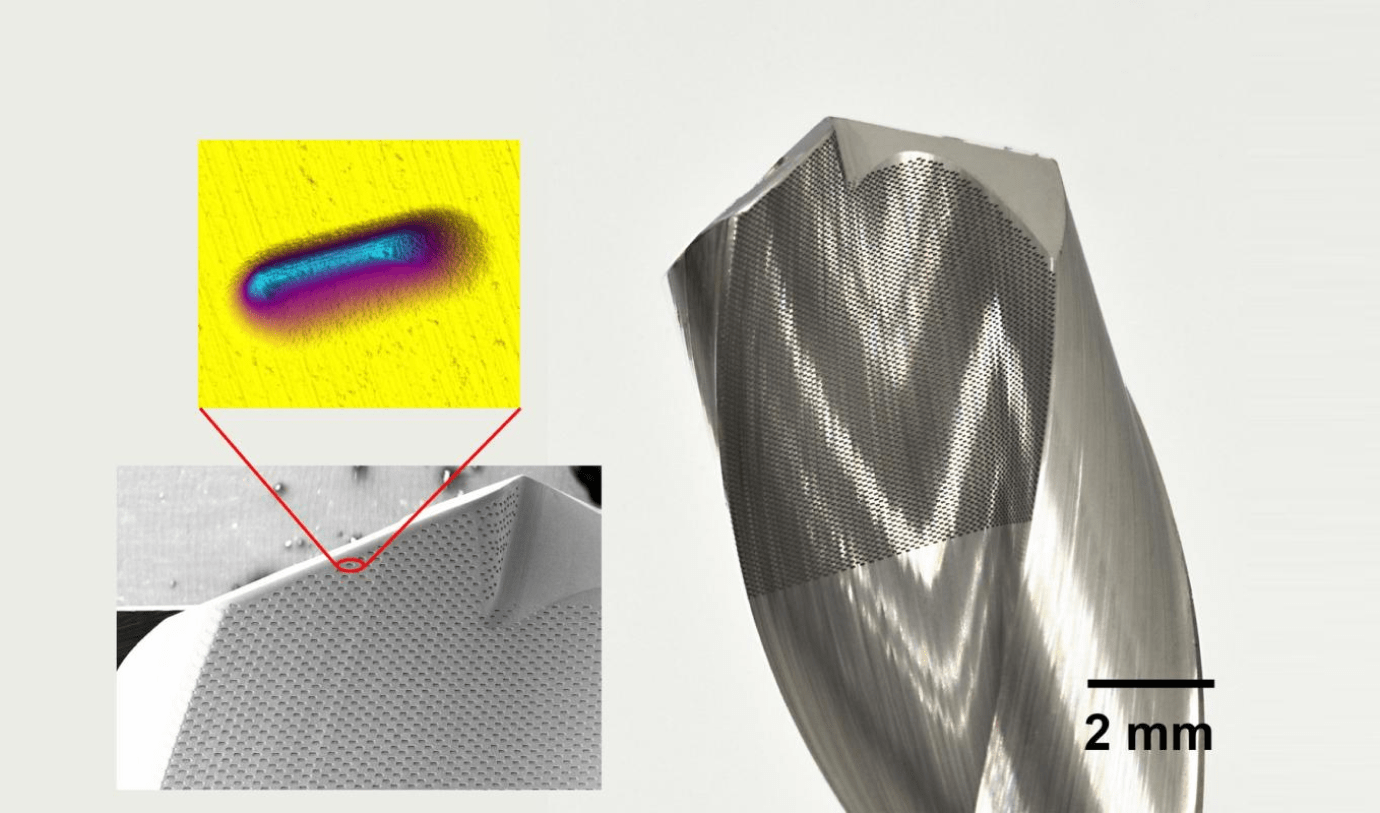

Micromachining is a manufacturing process that uses precision machine tools to create parts with very small dimensions. The term “micromachining” is typically used to refer to processes that create parts with dimensions of 0.1 mm or less.

Micromachining is used to create parts for a variety of industries, including aerospace, medical, and electronics. In the aerospace industry, micromachining is used to create parts for jet engines, satellites, and other aircraft components. In the medical industry, micromachining is used to create parts for surgical implants, medical devices, and other medical equipment. In the electronics industry, micromachining is used to create parts for computer chips, circuit boards, and other electronic components.

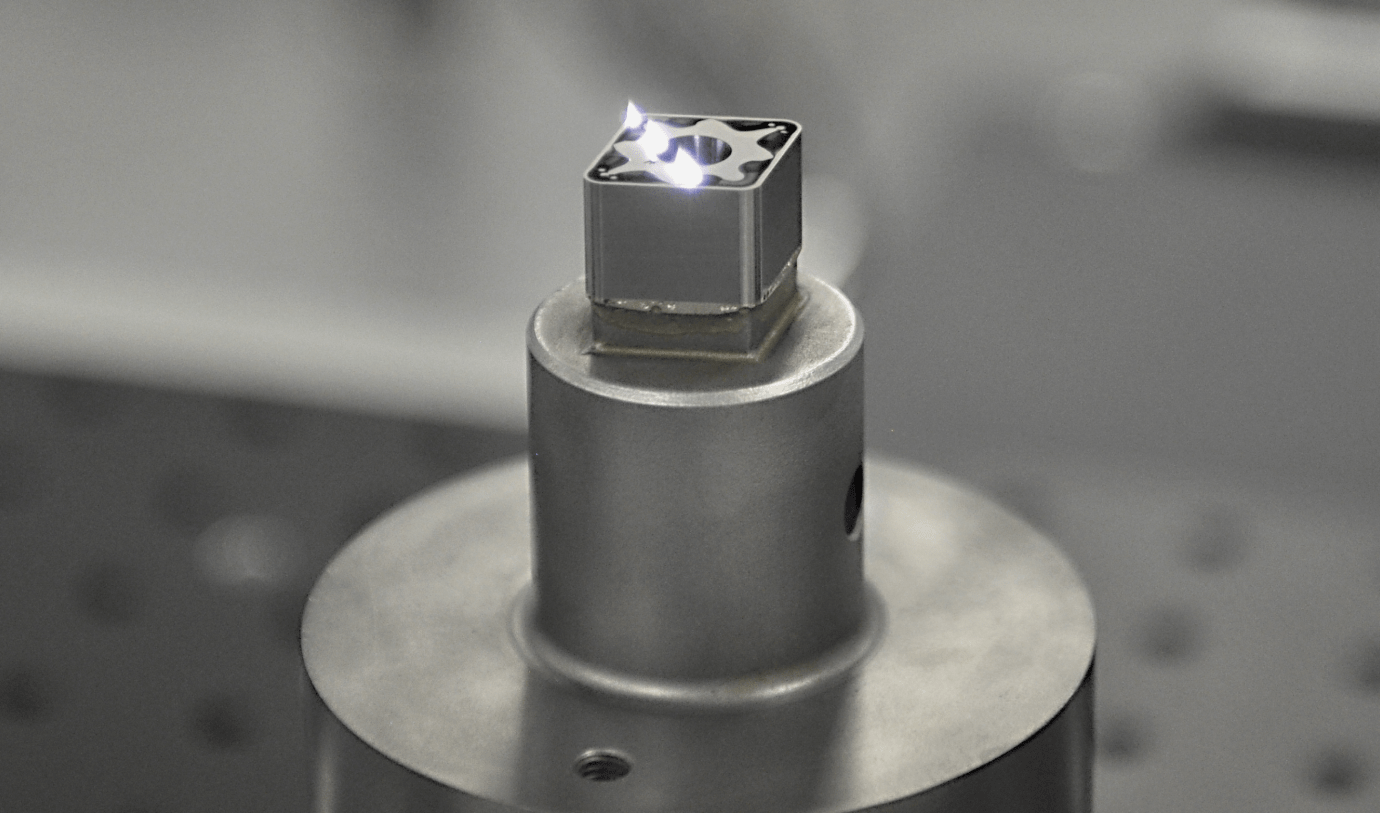

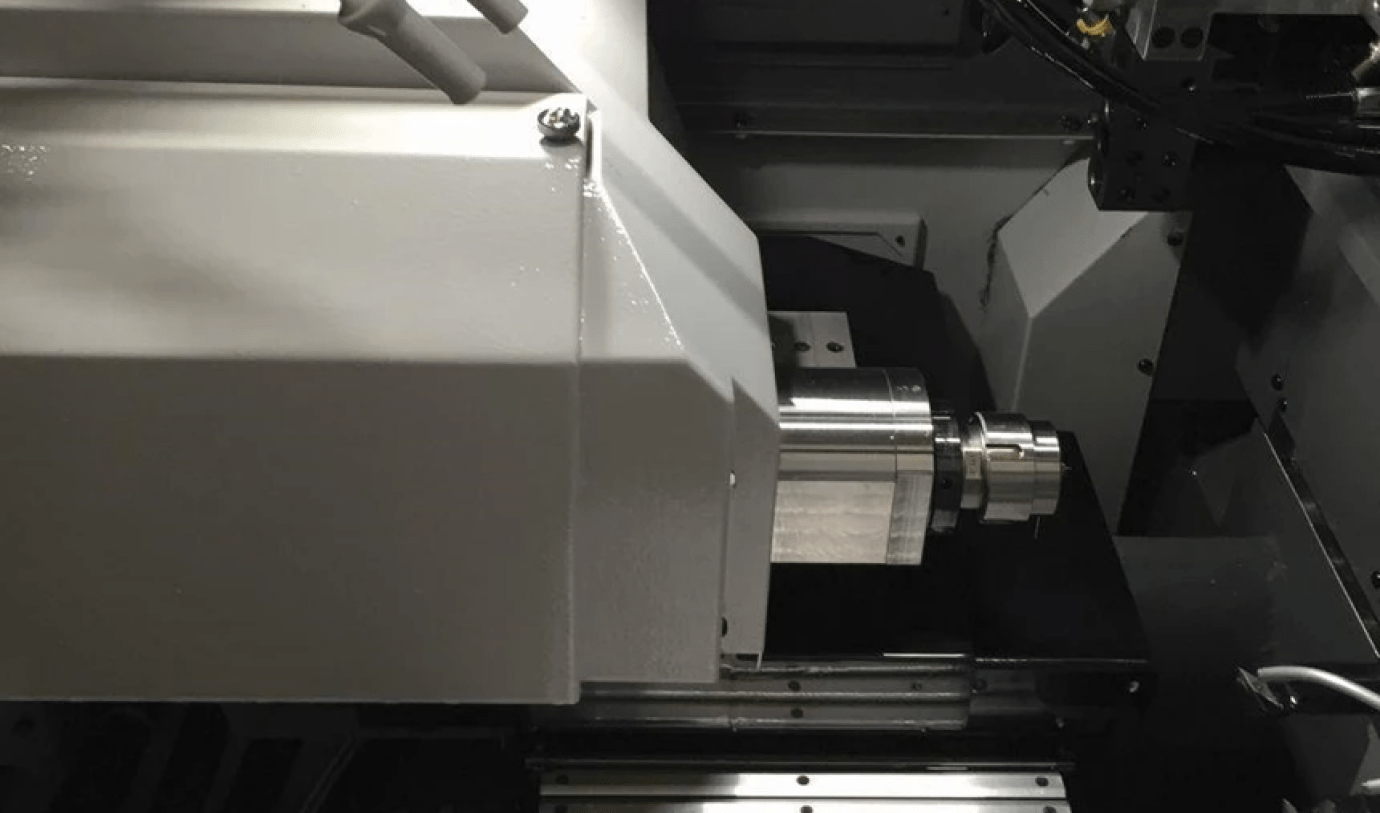

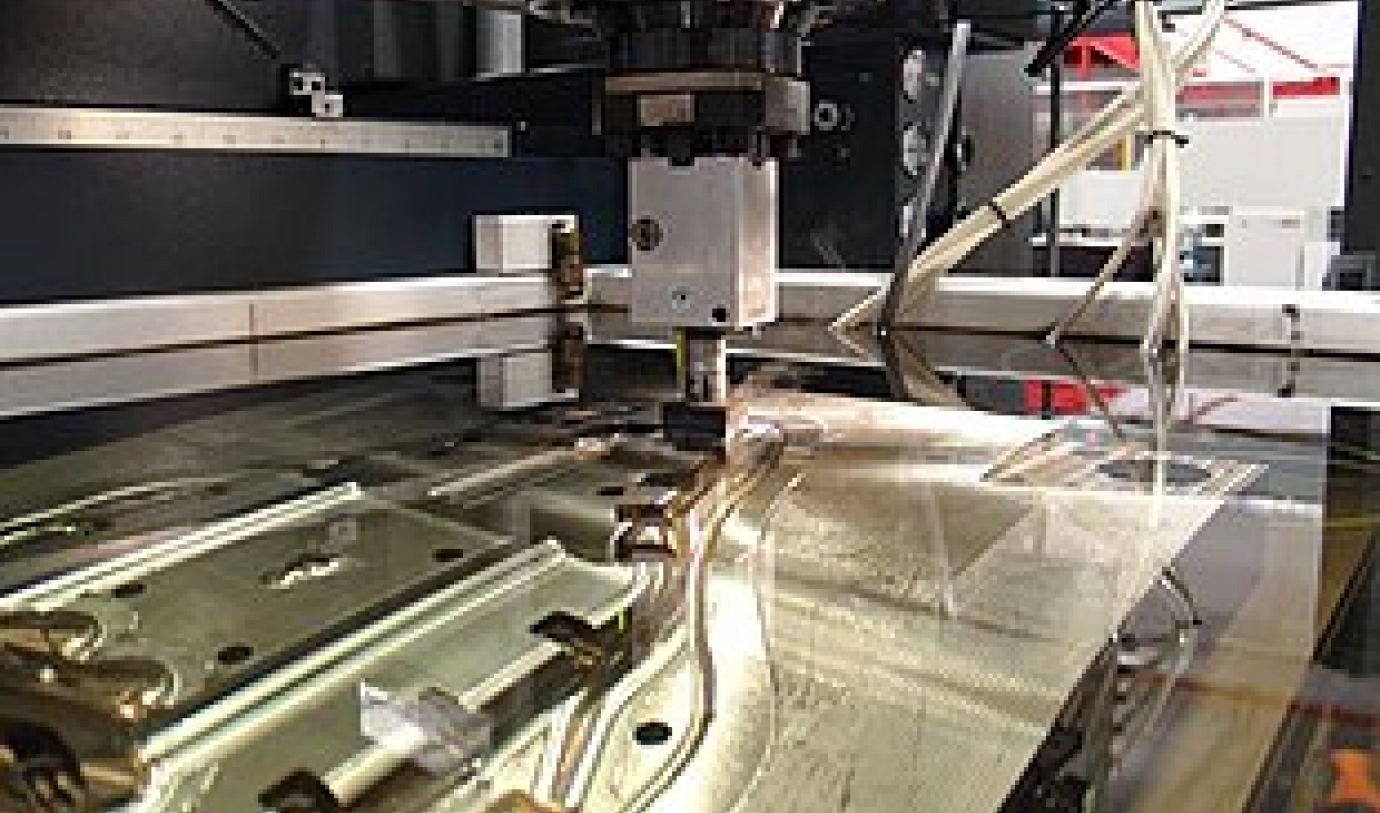

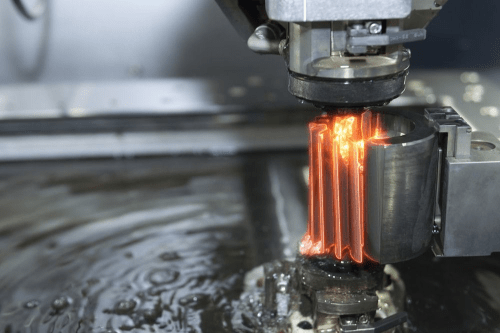

Micromachining requires a high level of precision and accuracy. The machines used for micromachining are typically computer-controlled (CNC) machines that can be programmed to move the cutting tool with extreme precision. The cutting tools used for micromachining are also very small and delicate.

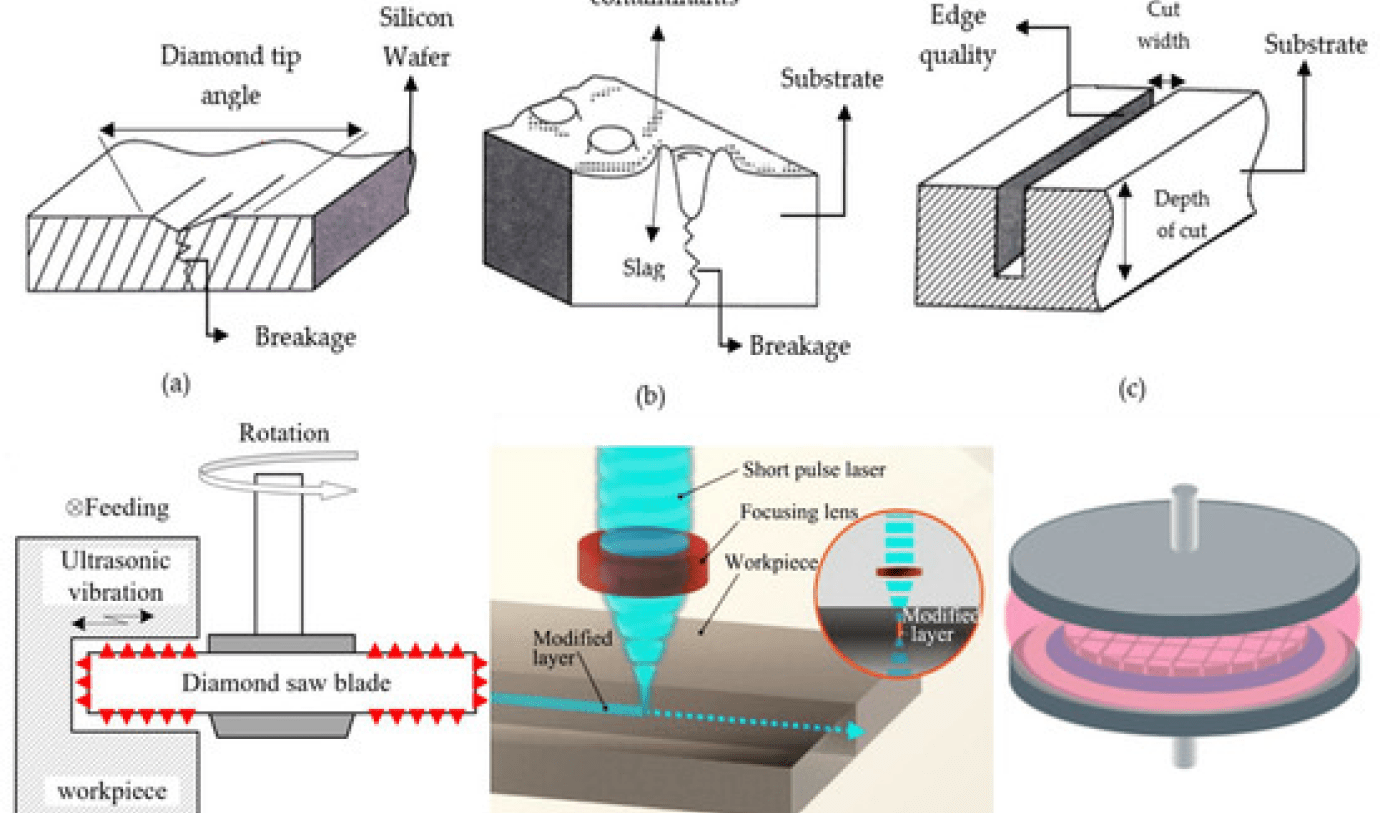

Some of the common micromachining processes include:

- Turning: This process is used to create cylindrical parts with very small diameters.

- Milling: This process is used to create flat and curved surfaces with very small features.

- Drilling: This process is used to create holes with very small diameters.

- Grinding: This process is used to smooth the surface of a part and remove any burrs or imperfections.

- Polishing: This process is used to create a mirror-like finish on a part.

Micromachining offers a number of advantages over other manufacturing processes, including:

- The ability to create parts with very small dimensions.

- The ability to create parts with very complex shapes and features.

- The ability to create parts from a variety of materials.

- The ability to create parts with very high precision and accuracy.

CNC services that use micromachining, including:

- Turning: Turning is a CNC process that uses a rotating tool to create cylindrical parts. Micromachining can be used to create very small diameter parts with very precise dimensions.

- Milling: Milling is a CNC process that uses a rotating tool to create flat and curved surfaces. Micromachining can be used to create very small features and complex shapes.

- Drilling: Drilling is a CNC process that uses a rotating tool to create holes. Micromachining can be used to create very small diameter holes with very precise dimensions.

- Grinding: Grinding is a CNC process that uses a rotating abrasive wheel to smooth the surface of a part and remove any burrs or imperfections. Micromachining can be used to create very smooth surfaces with very high precision.

- Polishing: Polishing is a CNC process that uses a rotating abrasive wheel to create a mirror-like finish on a part. Micromachining can be used to create very high-quality finishes on very small parts.

We are also able to provide micromachining repair and maintenance services.

Micromachining is a versatile manufacturing process that can be used to create a wide variety of parts for a variety of industries.

Here are some of the benefits of using Shiv CNC for your Micromachining needs:

- Smaller parts: Micromachining can create parts that are much smaller than what is possible with traditional machining methods.

- More precise parts: Micromachining can create parts with very tight tolerances.

- More complex parts: Micromachining can create parts with very complex shapes and features.

- Wide range of materials: Micromachining can be used to create parts from a variety of materials, including metal, plastic, and ceramic.

- High level of precision and accuracy: Micromachining offers a high level of precision and accuracy.

- Safe, reliable, and effective parts: Micromachining can be used to create parts that are safe, reliable, and effective.

Contact Shiv CNC today to learn more about our Micromachining services.

Shiv CNC is different from other micromachining companies as :

First, Shiv CNC has over 4 years of experience in micromachining. This experience has given us a deep understanding of the micromachining process and the challenges it presents. We have a team of experienced and skilled machinists who can create parts with very high precision and accuracy.

Second, Shiv CNC has a wide range of capabilities. We can create parts from a variety of materials, including metal, plastic, and ceramic. We can also perform a wide range of micromachining operations, including turning, milling, drilling, grinding, and polishing.

Third, Shiv CNC uses state-of-the-art CNC machines and CAD/CAM software to create parts with the highest level of precision and accuracy. Our CNC machines are equipped with the latest technology, and our CAD/CAM software allows us to design and engineer your parts to meet your specific requirements.

Fourth, Shiv CNC is committed to quality. We inspect our parts using state-of-the-art equipment to ensure that they meet your requirements. We also offer a wide range of maintenance services to help you keep your parts in good condition.

Fifth, Shiv CNC is committed to providing excellent customer service. We will work with you to understand your needs and requirements and to create parts that meet your expectations.

We have a deep understanding of the micromachining process, a wide range of capabilities, state-of-the-art equipment, and a commitment to quality and customer service.

Micromachining is used in a wide variety of applications, including:

- In the aerospace industry, micromachining is used to create parts for jet engines, such as fuel nozzles and turbine blades. These parts must be very small and precise in order to operate efficiently and effectively.

- In the medical industry, micromachining is used to create parts for surgical implants, such as pacemakers and artificial joints. These parts must be very small and precise in order to fit inside the human body and function properly.

- In the electronics industry, micromachining is used to create parts for computer chips, such as transistors and capacitors. These parts must be very small and precise in order to function properly.

- In the jewelry industry, micromachining is used to create jewelry with very intricate designs, such as necklaces and bracelets. These designs must be very small and precise in order to be attractive and durable.

- In the watchmaking industry, micromachining is used to create watches with very small and precise parts, such as the gears and springs. These parts must be very small and precise in order to keep accurate time.

- In the optics industry, micromachining is used to create optical components with very high precision, such as lenses and mirrors. These components must be very small and precise in order to produce clear images.

- In the automotive industry, micromachining is used to create parts for cars and other vehicles, such as brake rotors and fuel injectors. These parts must be very small and precise in order to operate safely and efficiently.

- In the manufacturing industry, micromachining is used to create parts for a variety of products, such as machines, tools, and appliances. These parts must be very small and precise in order to function properly.

Micromachining in Aerospace

Micromachining is a type of machining that uses very small tools to create very small features. This makes it ideal for manufacturing aerospace components, which often require precise and intricate parts.

Micromachining is a versatile and precise manufacturing technique that is used in a wide variety of aerospace applications. As the field of aerospace technology continues to advance, micromachining is likely to play an even greater role in the development of new and innovative aerospace components.

Micromachining in Aircraft

Micromachining is a versatile and precise manufacturing technique that is used in a wide variety of aircraft applications. As the field of aircraft technology continues to advance, micromachining is likely to play an even greater role in the development of new and innovative aircraft components.

Micro-machines are used in a variety of aircraft applications, such as fuel injectors, engine controls, and flight simulators. Micromachining is used to create micro-machines that are very small and can be precisely controlled. This allows for more effective and efficient operation.

Micromachining in Defence

Micromachining is a type of machining that uses very small tools to create very small features. This makes it ideal for manufacturing defense components, which often require precise and intricate parts.

Micromachining is a versatile and precise manufacturing technique that is used in a wide variety of defense applications. As the field of defense technology continues to advance, micromachining is likely to play an even greater role in the development of new and innovative defense components.

Micromachining in Medical

Micromachining is a type of machining that uses very small tools to create very small features. This makes it ideal for manufacturing medical devices, which often require precise and intricate parts.

Micromachining is a versatile and precise manufacturing technique that is used in a wide variety of medical applications. As the field of medicine continues to advance, micromachining is likely to play an even greater role in the development of new and innovative medical devices.