Sink/RAM EDM

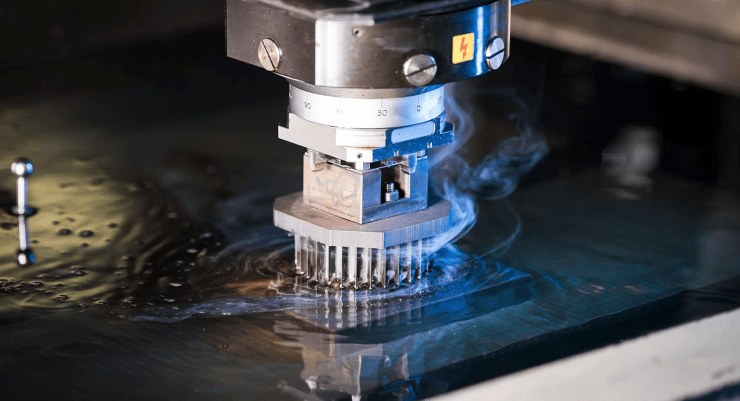

Sink/Ram EDM for the toughest materials, with the ultimate in surface finish and accuracy.

Sink/Ram EDM Services :

What is Sink/RAM EDM Services ?

Sink/RAM EDM, also known as wire-cutting EDM, is a precision machining process that uses electrical discharges to erode material away. A thin wire is fed through the workpiece and a high-voltage spark is created between the wire and the workpiece. The spark causes a localized melting and vaporization of the workpiece material, which is then removed by a flushing fluid.

Sink/RAM EDM is a versatile machining process that can be used to machine a wide variety of materials, including steel, stainless steel, titanium, and even hardened steel. It is also a very precise machining process, capable of producing parts with tolerances of +/- 0.0001″.

Sink/RAM EDM is often used to machine complex shapes and features that would be difficult or impossible to machine with other methods. For example, sink/RAMEDM can be used to machine intricate molds and dies, medical implants, and jewelry.

The Sink/RAM EDM process is divided into two steps: sinking and snagging. In the sinking step, the wire is fed through the workpiece, and the electrical discharges are used to erode a cavity in the workpiece. In the snagging step, the wire is fed through the cavity, and the electrical discharges are used to erode the sides of the cavity, creating a finished part.

Types of Sink/RAM EDM :

- Conventional sink/RAM EDM: This is the most common type of Sink/RAM EDM. It is a two-step process, as mentioned earlier, where the wire is first used to sink a cavity in the workpiece, and then the wire is used to snag the sides of the cavity to create a finished part.

- High-speed Sink/RAM EDM: This type of Sink/RAM EDM uses a higher voltage and a faster wire feed rate than conventional Sink/RAMEDM. This allows it to machine parts more quickly, but it also produces a rougher surface finish.

- Pulsed Sink/RAM EDM: This type of Sink/RAM EDM uses a pulsed voltage, which means that the voltage is turned on and off very quickly. This helps to reduce the heat buildup in the workpiece, which can lead to cracking.

- Die sinking EDM: This type of Sink/RAM EDM is specifically designed for machining molds and dies. It uses a thicker wire than conventional Sink/RAMEDM, which helps to reduce the wear on the wire.

Future of Sink/RAM EDM.

- The rise of micro-EDM: Micro-EDM is a variation of Sink/RAM EDM that is used to machine parts with very small features. Micro-EDM is becoming increasingly popular as the demand for smaller and more precise parts grows.

- The development of new EDM materials: New materials that are resistant to electrical discharge machining are being developed. This will expand the range of applications for Sink/RAM EDM and make it possible to machine parts that were previously impossible to machine.

- The use of EDM in additive manufacturing: EDM is being used in additive manufacturing to create complex parts that would be difficult or impossible to machine with other methods. This is an area of active research, and it is likely that EDM will play an increasingly important role in additive manufacturing in the future.

- The rise of automation: Sink/RAM EDM machines are becoming more automated, which will make them easier to operate and more productive. This will help to reduce the need for skilled operators, which is one of the challenges facing Sink/RAMEDM.

- The development of new applications: New applications for Sink/RAM EDM are being discovered all the time. For example, Sink/RAM EDM is being used to machine parts for the medical and aerospace industries. This will help to expand the market for Sink/RAM EDM and make it a more viable option for manufacturers.

- The improvement of surface finishes: The surface finishes of Sink/RAM EDM parts are constantly being improved. This is important for applications where a smooth surface finish is required, such as the medical and aerospace industries.

Overall, the future of Sink/RAM EDM is bright. The technology is continuing to develop, and new applications for Sink/RAM EDM are being discovered all the time. This makes Sink/RAMEDM a versatile and valuable machining process that is likely to be used for many years to come.

Here are some of the benefits of using Sink/RAM EDM machines :

- Reduced tooling costs: Sink/RAM EDM does not require the use of tooling, which can be expensive for other machining processes. This can save manufacturers a significant amount of money, especially when producing small batches of parts.

- No heat-affected zone: Sink/RAM EDM does not produce a heat-affected zone (HAZ), which is an area of material that has been affected by heat and is, therefore, weaker than the surrounding material. This makes Sink/RAM EDM a good choice for applications where the strength of the material is critical.

- No burrs: Sink/RAM EDM produces parts with no burrs, which is important for applications where a smooth surface finish is required.

- No residual stress: Sink/RAM EDM does not produce any residual stress in the workpiece, which can be a problem with other machining processes. Residual stress can cause parts to warp or crack, so it is important to avoid it whenever possible.

- Environmentally friendly: Sink/RAM EDM is a relatively environmentally friendly machining process. The only waste produced is the dielectric fluid, which can be recycled or disposed of properly.

How Shivay Enterprise is different from other Sink/RAM EDM machining service companies:

- We have a team of certified engineers: Shivay Enterprise has a team of engineers who are certified in Sink/RAM EDM machining. This means that they have met the highest standards of knowledge and skill in this field.

- We have a dedicated quality control team: Shivay Enterprise has a dedicated quality control team that inspects all of our parts before they are shipped to our customers. This ensures that our parts meet the highest standards of quality.

- We have a comprehensive warranty: Shivay Enterprise offers a comprehensive warranty on all of our parts. This means that our customers can be confident that their parts will be free from defects for a specified period of time.

- We have a global network of partners: Shivay Enterprise has a global network of partners that allows us to provide our customers with the best possible service. This means that we can source the materials and equipment we need from anywhere in the world, and we can deliver our parts to our customers anywhere in the world.

- We are committed to sustainability: Shivay Enterprise is committed to sustainability. We use environmentally friendly practices in our machining operations, and we recycle all of our waste materials.

- We are transparent in our pricing: Shivay Enterprise is transparent in our pricing. We offer our customers a clear and concise quote for all of our services.

- We are responsive to customer feedback: Shivay Enterprise is responsive to customer feedback. We listen to our customer’s needs and suggestions, and we use this feedback to improve our services.

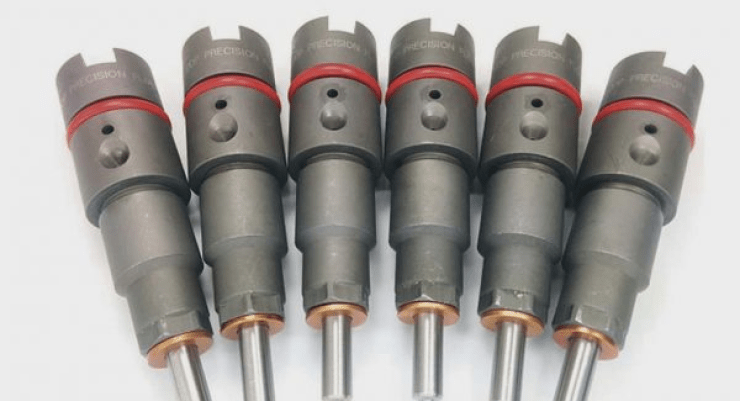

Sink/RAM EDM machining service is used in a wide variety of applications, including:

- Molds and dies: Sink/RAMEDM is often used to machine molds and dies for plastics and other materials. This is because sink/ram EDM can produce molds and dies with complex shapes and features that would be difficult or impossible to machine with other methods.

- Medical implants: Sink/RAMEDM is often used to machine medical implants, such as pacemakers and artificial joints. This is because Sink/RAM EDM can produce medical implants with a high degree of precision and a smooth surface finish that is essential for the safe and effective function of medical implants.

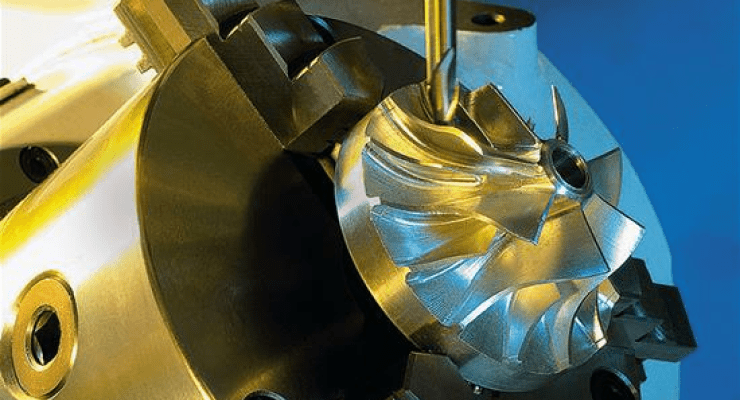

- Aerospace: Sink/RAMEDM is often used to machine aerospace components, such as turbine blades and landing gear. This is because Sink/RAMEDM can produce aerospace components with a high degree of precision and a smooth surface finish that is essential for the safe and efficient operation of aircraft.

- Defense: Sink/RAMEDM is often used to machine defense components, such as gun barrels and missile components. This is because sSink/RAM EDM can produce defense components with a high degree of precision and a smooth surface finish that is essential for the safe and effective operation of defense systems.

- Tooling: Sink/RAMEDM is often used for machine tooling, such as cutting tools and dies. This is because Sink/RAMEDM can produce tooling with a high degree of precision and a smooth surface finish that is essential for the efficient and accurate machining of other parts.

How Shivay Enterprise can help you with Sink/RAM EDM maintenance servicing:

- Preventative maintenance: Shivay Enterprise can help you develop a preventative maintenance plan for your Sink/RAM EDM machine. This will help to identify and correct potential problems before they cause downtime or damage to your machine.

- Troubleshooting: If your Sink/RAM EDM machine is not working properly, Shivay Enterprise can help you troubleshoot the problem and identify the root cause. This will help you to get your machine back up and running quickly and efficiently.

- Repairs: If your Sink/RAM EDM machine needs repairs, Shivay Enterprise can provide you with high-quality, affordable repairs. We have a team of experienced technicians who are familiar with all types of Sink/RAM EDM machines.

- Upgrades: If you are looking to upgrade your Sink/RAM EDM machine, Shivay Enterprise can help you choose the right upgrades for your needs. We can also help you install and configure the new upgrades.

- Training: Shivay Enterprise can provide you with training on how to operate and maintain your Sink/RAM EDM machine. This training will help you to get the most out of your machine and ensure that it is properly maintained.

We understand that Sink/RAM EDM machines are essential for your business, and we are committed to providing you with the best possible maintenance services. We have a team of experienced technicians who are familiar with all types of Sink/RAM EDM machines. We can help you with preventative maintenance, troubleshooting, repairs, upgrades, and training. We are committed to helping you keep your Sink/RAM EDM machine running smoothly and efficiently.

Sink/RAM EDM in Food Industry

Sink/ram EDM is a valuable tool for the food industry. It allows manufacturers to produce high-quality components with complex geometries that would be difficult or impossible to machine using other methods. This helps to ensure that food products are safe and sanitary.

The type of EDM machine used for sink/ram EDM in the food industry is typically a wire EDM machine. Wire EDM machines use a thin wire to erode material from the workpiece.

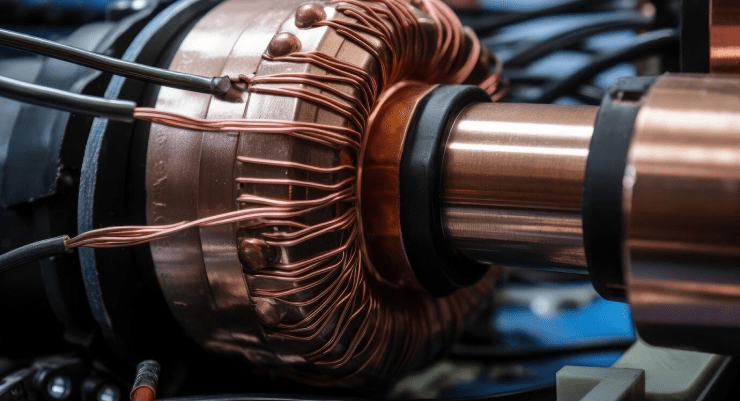

The wire used in sink/ram EDM is typically made from a copper alloy. The wire is fed through the machine at a controlled speed, and the electrical discharge is created between the wire and the workpiece.

Sink/RAM EDM in Pharmacy

Sink/RAM EDM is an electrical discharge machining process that uses a wire to erode material from a workpiece. This process is typically used to create complex cavities and holes in hard and difficult-to-machine materials, such as stainless steel and titanium.

Sink/ram EDM can produce components with very tight tolerances, which is important for the pharmaceutical industry.Sink/ram EDM can be used to produce complex geometries that would be difficult or impossible to machine using other methods.

Sink/ram EDM can be a cost-effective way to produce pharmaceutical components, especially when compared to other methods such as milling or turning.

Sink/RAM EDM in Energy

Sink/ram EDM is a precision process that can produce components with very tight tolerances. This makes it ideal for the energy industry, where components must meet strict safety and performance requirements.

The type of EDM machine used for sink/ram EDM in the energy industry is typically a wire EDM machine. Wire EDM machines use a thin wire to erode material from the workpiece.

The wire used in sink/ram EDM is typically made from a copper alloy. The wire is fed through the machine at a controlled speed, and the electrical discharge is created between the wire and the workpiece.

Sink/RAM EDM in Aerospace

The wire used in sink/ram EDM is typically made from a copper alloy. The wire is fed through the machine at a controlled speed, and the electrical discharge is created between the wire and the workpiece.

The parameters of the electrical discharge, such as the voltage, current, and pulse duration, are adjusted to control the rate of material removal.

Sink/ram EDM is a precision process that can produce components with very tight tolerances. This makes it ideal for the aerospace industry, where components must meet strict safety and performance requirements.