Wire EDM

Wire EDM: Keep your machines running smoothly, so you can produce high-quality parts and components on time and on budget, and exceed your customers’ expectations.

Wire EDM Services :

What is Wire EDM Services ?

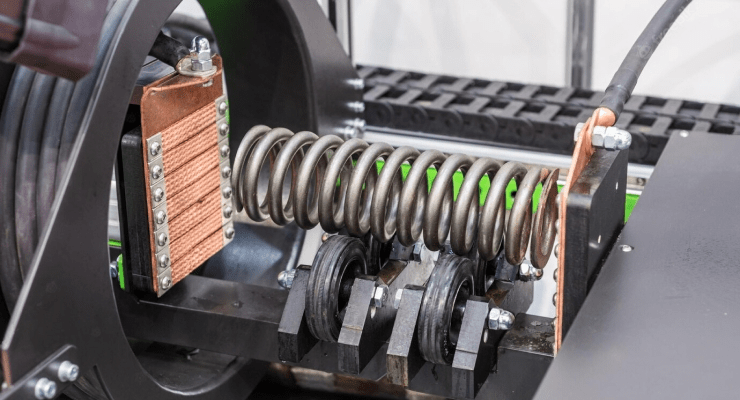

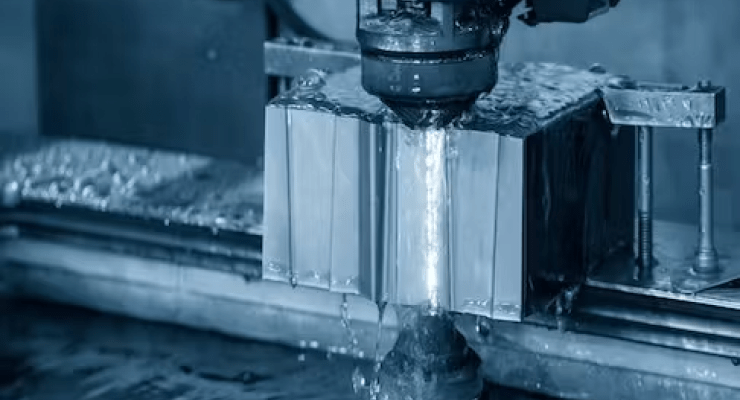

Wire EDM, or wire electrical discharge machining, is a type of electrical discharge machining (EDM) that uses a thin wire to cut away material. The wire is fed through the workpiece, and the sparks from the electric discharge erode the material away. Wire EDM is often used to machine complex geometries, such as holes and slots.

The wire EDM process is relatively slow, but it is very precise. Wire EDM machines can produce parts with very tight tolerances, and they can also machine difficult-to-cut materials, such as hardened steel and titanium.

The wire EDM process is a complex process, and there are a number of factors that can affect the quality of the finished part. These factors include the type of wire used, the dielectric fluid, the voltage, and current settings, and the feed rate.

Wire EDM is a versatile process that can be used to machine a wide variety of materials. However, it is important to note that wire EDM is not a cost-effective process for large parts. For large parts, other machining processes, such as milling or turning, are typically more cost-effective.

Types of wire EDM :

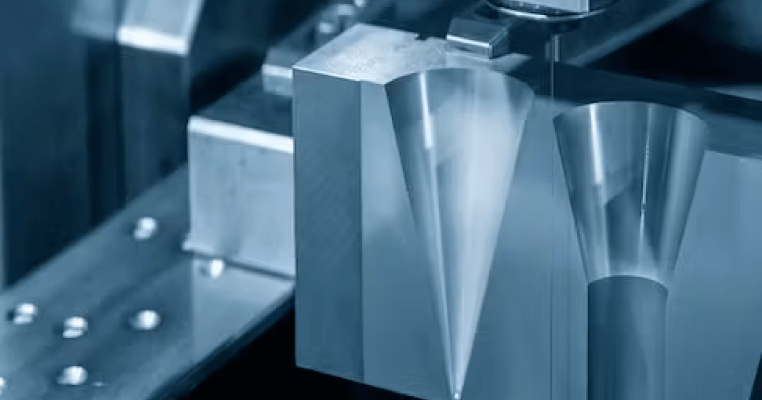

- Sinker EDM: Sinker EDM is the most common type of wire EDM. In sinker EDM, the wire is plunged into the workpiece, and the sparks from the electric discharge erode the material away. Sinker EDM is often used to machine cavities and other internal features.

- Cutting EDM: Cutting EDM is a type of wire EDM that is used to cut away material from the surface of the workpiece. Cutting EDM is often used to machine holes and slots.

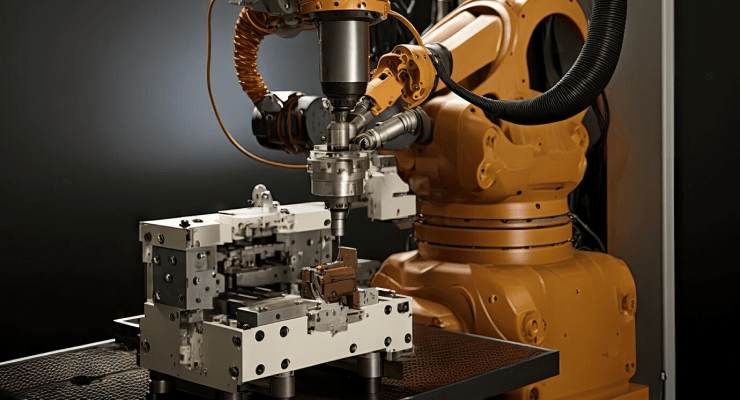

- Wire EDM machines: Wire EDM machines are typically computer-controlled. The computer controls the movement of the wire, the voltage and current settings, and the feed rate. Wire EDM machines can be either CNC machines or NC machines. CNC machines are more precise than NC machines, but they are also more expensive.

- Dielectric fluids: Dielectric fluids are used in wire EDM to insulate the wire from the workpiece and to carry away the heat from the electric discharge. The most common dielectric fluids are kerosene, mineral oil, and deionized water.

The wire EDM process is typically divided into four steps:

- Wire preparation: The wire is first prepared by cutting it to the desired length and sharpening the tip.

- Workpiece preparation: The workpiece is then prepared by cleaning it and applying a dielectric fluid.

- Machining: The wire is fed through the workpiece, and the sparks from the electric discharge erode the material away.

- Post-processing: The workpiece is then cleaned and inspected.

Here are some of the challenges of using wire EDM:

- Slow process: Wire EDM is a relatively slow process.

- Cost: Wire EDM can be a costly process, especially for large parts.

- Skill level: Wire EDM requires a high level of skill to operate.

Wire EDM is a versatile and precise machining process that can be used to produce a wide variety of parts. However, it is important to note that wire EDM is not a cost-effective process for large parts.

Here are some of the benefits of using Wire EDM machines :

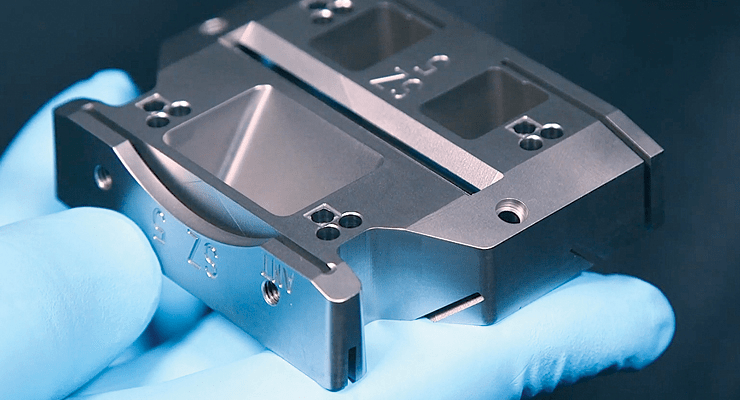

- Precision: Wire EDM can produce parts with very tight tolerances.

- Complex geometries: Wire EDM can be used to machine complex geometries, such as holes and slots.

- Difficult-to-cut materials: Wire EDM can machine difficult-to-cut materials, such as hardened steel and titanium.

- Smooth surfaces: Wire EDM can produce parts with smooth surfaces.

- Cost-effectiveness: Wire EDM can be a cost-effective process for small to medium-sized parts.

- Versatility: Wire EDM can be used to machine a wide variety of materials.

- Speed: Wire EDM can be a fast process for small to medium-sized parts.

- No burrs: Wire EDM produces parts with no burrs, which is important for some applications.

- Minimal heat-affected zone: Wire EDM produces a minimal heat-affected zone, which means that the material properties of the workpiece are not significantly changed.

- No tool wear: The wire is constantly being replaced, so there is no tool wear. This means that the wire EDM process can be used to machine parts with very high accuracy.

How Shivay Enterprise is different from other Wire EDM machining service companies:

- Expertise: Shivay Enterprise’s team of engineers and machinists have over 20 years of experience in wire EDM machining. This experience gives us the knowledge and skills to machine complex parts with tight tolerances. We have a deep understanding of the wire EDM process, and we are able to use this knowledge to optimize the machining process for each individual part.

- Technology: Shivay Enterprise uses the latest wire EDM technology. This technology allows us to machine parts faster and more accurately than other companies. We use high-speed wire EDM machines that can machine parts at speeds of up to 100 inches per minute. We also use advanced dielectric fluids that help to improve the machining process.

- Capabilities: Shivay Enterprise can machine a wide variety of materials, including steel, stainless steel, titanium, and other hard materials. We can also machine complex geometries, such as holes, slots, and contours. We have the experience and capabilities to machine parts for a wide range of industries, including aerospace, medical, and automotive.

- Quality: Shivay Enterprise is committed to quality. We have a strict quality control process in place to ensure that our parts meet our high standards. We inspect each part at multiple stages of the machining process to ensure that it meets our specifications. We also have a team of experienced quality engineers who are responsible for ensuring that our quality standards are met.

- Customer service: Shivay Enterprise provides excellent customer service. We are always available to answer your questions and help you with your project. We understand that your time is valuable, and we work hard to make sure that your project is completed on time and to your satisfaction.

- Flexibility: Shivay Enterprise is flexible and can accommodate a wide range of projects. We can machine parts in small quantities or large quantities. We can also machine parts on short notice or on long-term projects.

- Pricing: Shivay Enterprise offers competitive pricing. We are committed to providing our customers with the best possible value for their money.

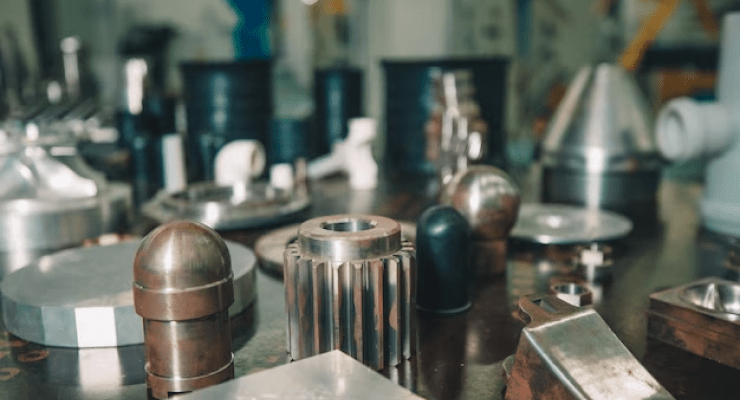

Wire EDM machining service is used in a wide variety of applications, including:

- Tool and die: Wire EDM is used to machine parts for tools and dies, such as punches, dies, and molds. This includes parts such as intricate shapes and sharp edges.

- Precision components: Wire EDM is used to machine precision components, such as gears, bearings, and valves. This includes parts that require tight tolerances and smooth surfaces.

- Orthopedics: Wire EDM is used to machine parts for orthopedic implants, such as artificial joints and bone screws. This includes parts that require high strength and durability.

- Aerospace: Wire EDM is used to machine parts for aircraft, spacecraft, and missiles. This includes parts such as turbine blades, fuel nozzles, and landing gear components.

- Medical: Wire EDM is used to machine parts for medical implants, surgical instruments, and other medical devices. This includes parts such as heart valves, stents, and surgical saw blades.

- Machine tools: Wire EDM is used to machine parts for machine tools, such as milling machines and lathes. This includes parts such as tool holders, fixtures, and cutting inserts.

How Shivay Enterprise can help you with wire EDM maintenance servicing:

- We can help you troubleshoot and diagnose any problems with your wire EDM machine. We have the experience and expertise to identify the source of the problem and recommend a solution.

- We can provide preventive maintenance services for your wire EDM machine. This will help to keep your machine running smoothly and prevent major problems from occurring.

- We can repair or replace any worn or damaged parts on your wire EDM machine. We have a wide inventory of parts and we can custom-build parts if necessary.

- We can provide training on how to operate and maintain your wire EDM machine. This will help you to get the most out of your machine and prevent problems from occurring.

- We use only high-quality parts and materials. This ensures that your machine will be repaired or replaced to the highest standards.

- We offer a 1-year warranty on all repairs and replacements. This gives you peace of mind knowing that your machine is covered in the event of any problems.

- We are a certified wire EDM repair center. This means that we have the expertise and experience to repair your machine to the highest standards.

Wire EDM in Aircraft

Wire EDM is a valuable tool for the aircraft industry. It allows manufacturers to produce high-quality components with complex geometries that would be difficult or impossible to machine using other methods. This helps to ensure that aircraft are safe and reliable.

Wire EDM can be a cost-effective way to produce aircraft components, especially when compared to other methods such as milling or turning.

Wire EDM is a precision process that can produce components with very tight tolerances. This makes it ideal for the aircraft industry, where components must meet strict safety and performance requirements.

Wire EDM in Military

Wire EDM is a valuable tool for the military. It allows manufacturers to produce high-quality components with complex geometries that would be difficult or impossible to machine using other methods. This helps to ensure that military equipment is safe and effective.

wire EDM is a versatile and precise process that can be used to produce a variety of military components with high tolerances and complex geometries.

Wire EDM can be a cost-effective way to produce military components, especially when compared to other methods such as milling or turning.

Wire EDM in Medical

Wire EDM is a valuable tool for the medical industry. It allows manufacturers to produce high-quality components with complex geometries that would be difficult or impossible to machine using other methods. This helps to ensure that medical procedures are safe and effective.

wire EDM is a versatile and precise process that can be used to produce a variety of medical components with high tolerances and complex geometries.

Wire EDM in Oil & Gas

Wire EDM is an electrical discharge machining process that uses a thin wire to erode material from a workpiece. This process is typically used to create complex shapes and cavities in hard and difficult-to-machine materials, such as steel, stainless steel, and titanium.

Wire EDM is a valuable tool for the oil and gas industry. It allows manufacturers to produce high-quality components with complex geometries that would be difficult or impossible to machine using other methods. This helps to ensure that oil and gas operations are safe and efficient.